|

Functions

|

Parameter

|

BeNano 180 Zeta Pro

|

BeNano 180 Zeta

|

BeNano 90 Zeta

|

BeNano Zeta

|

BeNano 180 Pro

|

BeNano 180

|

BeNano 90

|

|

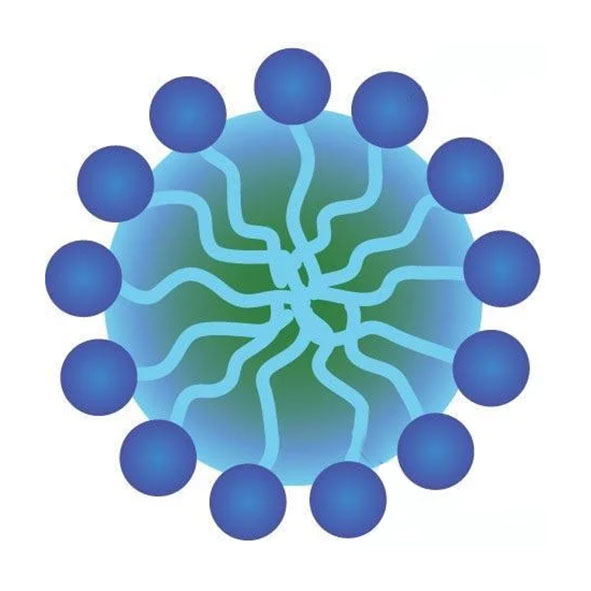

Size

measurement

|

Size

measurement range

|

0.3 nm – 15 μm*

|

0.3 nm – 10 μm*

|

0.3 nm – 15 μm*

|

N/A

|

0.3 nm – 15 μm*

|

0.3 nm -10 μm*

|

0.3 nm – 15 μm*

|

|

Sample volume

|

3 μL – 1 mL*

|

40 μL – 1 mL*

|

3 μL – 1 mL*

|

N/A

|

3 μL – 1 mL*

|

40 μL – 1 mL*

|

3 μL – 1 mL*

|

|

Detection angle

|

90° & 173° & 12°

|

173° & 12°

|

90° & 12°

|

N/A

|

90° & 173°

|

173°

|

90°

|

|

Analysis algorithm

|

Cumulants, General Mode,

CONTIN

|

Cumulants, General Mode,

CONTIN

|

Cumulants, General Mode,

CONTIN

|

N/A

|

Cumulants, General Mode,

CONTIN

|

Cumulants, General Mode,

CONTIN

|

Cumulants, General Mode,

CONTIN

|

|

Upper limit of

concentration range

|

40% w/v*

|

40% w/v*

|

Optically clear+

|

N/A

|

40% w/v*

|

40% w/v*

|

Optically clear†

|

|

Detection position

|

Movable position

0.4 – 5 mm

|

Movable position

0.4 – 5 mm

|

Fixed position

5 mm

|

N/A

|

Movable position

0.4 – 5 mm

|

Movable position

0.4 – 5 mm

|

Fixed position

5 mm

|

|

Zeta potential

measurement

|

Detection angle

|

12°

|

12°

|

12°

|

12°

|

N/A

|

N/A

|

N/A

|

|

Zeta potential

measurement range

|

No actual limitation

|

No actual limitation

|

No actual limitation

|

No actual limitation

|

N/A

|

N/A

|

N/A

|

|

Electrophoretic mobility

|

> ± 20 μm·cm/V·s

|

> ± 20 μm·cm/V·s

|

> ± 20 μm·cm/V·s

|

> ± 20 μm·cm/V·s

|

N/A

|

N/A

|

N/A

|

|

Conductivity

|

0 – 260 mS/cm

|

0 – 260 mS/cm

|

0 – 260 mS/cm

|

0 – 260 mS/cm

|

N/A

|

N/A

|

N/A

|

|

Sample volume

|

0.75 – 1 mL

|

0.75 – 1 mL

|

0.75 – 1 mL

|

0.75 – 1 mL

|

N/A

|

N/A

|

N/A

|

|

Sample size

|

2 nm – 110 μm

|

2 nm – 110 μm

|

2 nm – 110 μm

|

2 nm – 110 μm

|

N/A

|

N/A

|

N/A

|

|

Other

measurements

|

Molecular weight

(Mw)

|

342 Da – 2 x 107 Da* |

342 Da – 2 x 107 Da* |

342 Da – 2 x 107 Da*

|

N/A

|

342 Da – 2 x 107 Da*

|

342 Da – 2 x 107 Da*

|

342 Da – 2 x 107 Da*

|

|

Viscosity

|

0.01 cp – 100 cp*

|

0.01 cp – 100 cp*

|

0.01 cp – 100 cp*

|

N/A

|

0.01 cp – 100 cp*

|

0.01 cp – 100 cp*

|

0.01 cp – 100 cp*

|

|

Interaction parameter

KD

|

No actual limitation

|

No actual limitation

|

No actual limitation

|

N/A

|

No actual limitation

|

No actual limitation

|

No actual limitation

|

|

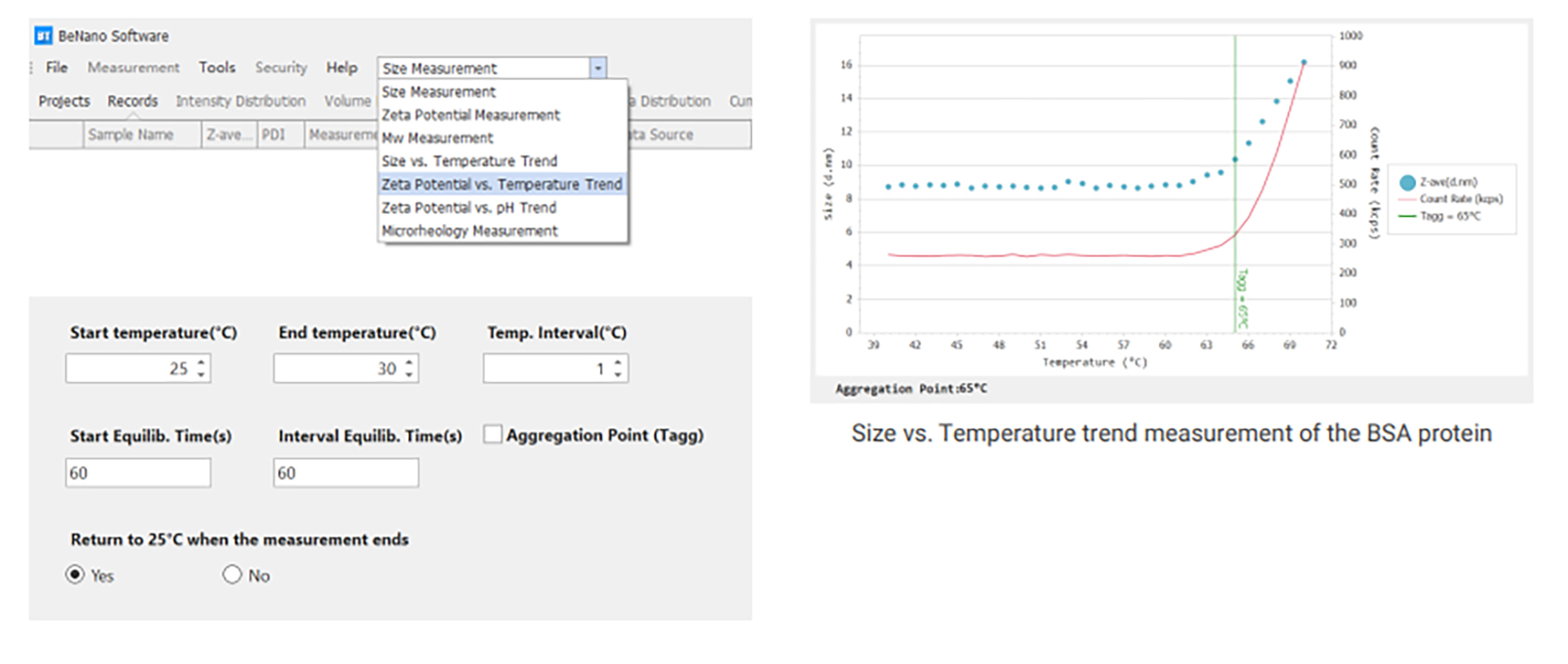

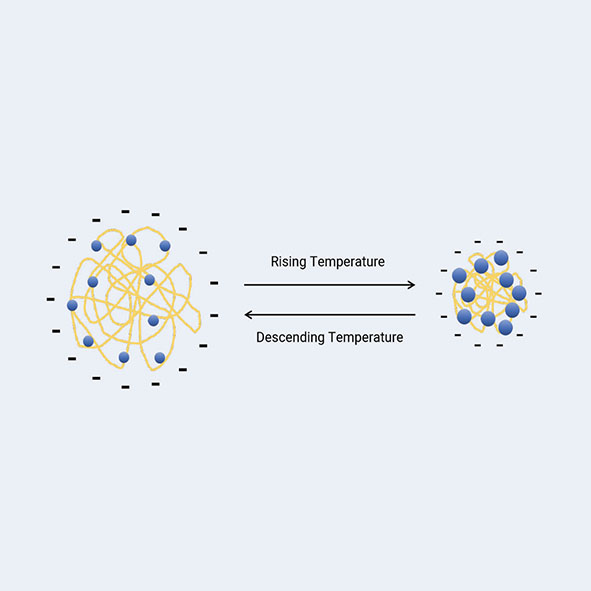

Trend measurement

|

Time and temperature

|

Time and temperature

|

Time and temperature

|

Time and temperature

|

Time and temperature

|

Time and temperature

|

Time and temperature

|

|

System

parameters

|

Temperature

control range

|

-15℃ – 110℃,

±0.1℃

|

-15℃ – 110℃,

±0.1℃

|

-15℃ – 110℃,

±0.1℃ |

-15℃ – 110℃,

±0.1℃

|

-15℃ – 110℃,

±0.1℃

|

-15℃ – 110℃,

±0.1℃

|

-15℃ – 110℃,

±0.1℃

|

|

Condensation control

|

Dry air or nitrogen

|

Dry air or nitrogen

|

Dry air or nitrogen

|

Dry air or nitrogen

|

Dry air or nitrogen

|

Dry air or nitrogen

|

Dry air or nitrogen

|

|

Laser source

|

50 mW Solid-state laser, 671 nm#, Class 1

|

50 mW Solid-state laser, 671 nm#, Class 1

|

50 mW Solid-state laser, 671 nm#, Class 1

|

50 mW Solid-state laser, 671 nm#, Class 1

|

50 mW Solid-state laser, 671 nm#, Class 1

|

50 mW Solid-state laser, 671 nm#, Class 1

|

50 mW Solid-state laser, 671 nm#, Class 1

|

|

Correlator

|

Up to 4000 channels,

1011 linear

dynamic range

|

Up to 4000 channels,

1011 linear

dynamic range

|

Up to 4000 channels,

1011 linear

dynamic range

|

Up to 4000 channels,

1011 linear

dynamic range

|

Up to 4000 channels,

1011 linear

dynamic range

|

Up to 4000 channels,

1011 linear

dynamic range

|

Up to 4000 channels,

1011 linear

dynamic range

|

|

Detector

|

Avalanche photodiode

(APD)

|

Avalanche photodiode

(APD)

|

Avalanche photodiode

(APD)

|

Avalanche photodiode

(APD)

|

Avalanche photodiode

(APD)

|

Avalanche photodiode

(APD)

|

Avalanche photodiode

(APD)

|

|

Intensity control

|

0.0001% – 100%,

manual or automatic

|

0.0001% – 100%,

manual or automatic

|

0.0001% – 100%,

manual or automatic

|

0.0001% – 100%,

manual or automatic

|

0.0001% – 100%,

manual or automatic

|

0.0001% – 100%,

manual or automatic

|

0.0001% – 100%,

manual or automatic

|

|

Dimensions

(L x W x H)

|

62.5 x 40 x 24.5 cm

(22 kg)

|

62.5 x 40 x 24.5 cm

(22 kg)

|

62.5 x 40 x 24.5 cm

(22 kg)

|

62.5 x 40 x 24.5 cm

(22 kg)

|

62.5 x 40 x 24.5 cm

(22 kg)

|

62.5 x 40 x 24.5 cm

(22 kg)

|

62.5 x 40 x 24.5 cm

(22 kg)

|

|

Power supply

|

AC 100-240 V,

50-60 Hz, 4A

|

AC 100-240 V,

50-60 Hz, 4A

|

AC 100-240 V,

50-60 Hz, 4A

|

AC 100-240 V,

50-60 Hz, 4A

|

AC 100-240 V,

50-60 Hz, 4A

|

AC 100-240 V,

50-60 Hz, 4A

|

AC 100-240 V,

50-60 Hz, 4A

|

|

Conformity

to standards

|

21 CFR Part 11, ISO 13321, ISO 22412, ISO 13099

|

21 CFR Part 11, ISO 13321, ISO 22412, ISO 13099

|

21 CFR Part 11, ISO 13321, ISO 22412, ISO 13099

|

21 CFR Part 11, ISO 13321, ISO 22412, ISO 13099

|

21 CFR Part 11, ISO 13321, ISO 22412, ISO 13099

|

21 CFR Part 11, ISO 13321, ISO 22412, ISO 13099

|

21 CFR Part 11, ISO 13321, ISO 22412, ISO 13099

|

|

Optional Accessories

|

Disposable

micro-volume cuvette

|

40 – 50 μL

|

40 – 50 μL

|

40 – 50 μL

|

N/A

|

40 – 50 μL

|

40 – 50 μL

|

40 – 50 μL

|

|

Micro-volume

glass cuvette

|

25 μL

|

N/A

|

25 μL

|

N/A

|

25 μL

|

N/A

|

25 μL

|

|

Glass cuvette

with round opening

|

1 mL

|

1 mL

|

1 mL

|

N/A

|

1 mL

|

1 mL

|

1 mL

|

|

Capillary sizing cell

|

3 – 5 μL

|

N/A

|

3 – 5 μL

|

N/A

|

3 – 5 μL

|

N/A

|

3 – 5 μL

|

|

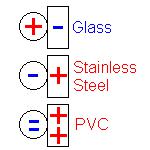

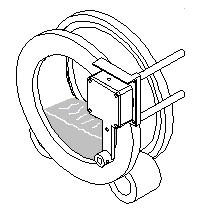

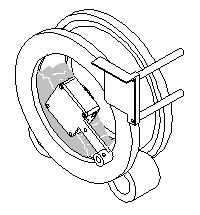

Dip cell kit

|

1 – 1.5 mL,

zeta potential measurement

for organic-based samples

|

1 – 1.5 mL,

zeta potential measurement

for organic-based samples

|

1 – 1.5 mL,

zeta potential measurement

for organic-based samples

|

1 – 1.5 mL,

zeta potential measurement

for organic-based samples

|

N/A

|

N/A

|

N/A

|

|

* Dependent on samples and accessories

† Up to 40% w/v using capillary sizing cell

# 10mW 633nm He-Ne laser available on request

|