Technology

Adsorption of Mixed Gases

Adsorption of mixtures: Dynamic sorption of gas and vapor mixtures

Challenges such as the adsorption of CO2 from dry and moist air, the adsorption of methane from biogas or the differentiation of the relevant physisorption behavior of adsorbents in gas and vapor mixtures are different from classical methods for texture determination. The main reason here is the fact, that a sorption of mixtures is occurring and the mixture needs to be separated accordingly in order to discover, which component is adsorbed at which magnitude.

Especially the selectivity plays a crucial role in the adsorption of mixtures, since the task requires the stronger adsorption of one component within the mixture in comparison to other residual components. In order to predict or model technical processes and extract data with practical relevance, the following investigations become more and more important:

- dynamic adsorption and desorption from a gas flow

- determination and evaluation of breakthrough curves

- investigation of sorption kinetics

- investigation of co-adsorption and displacement effects

- determination of sorption selectivity

- determination of sorption equilibria in gas and vapor mixtures

- scaling of technical sorption processes

- investigation of heat balance in dynamic adsorption processes

Analytical method

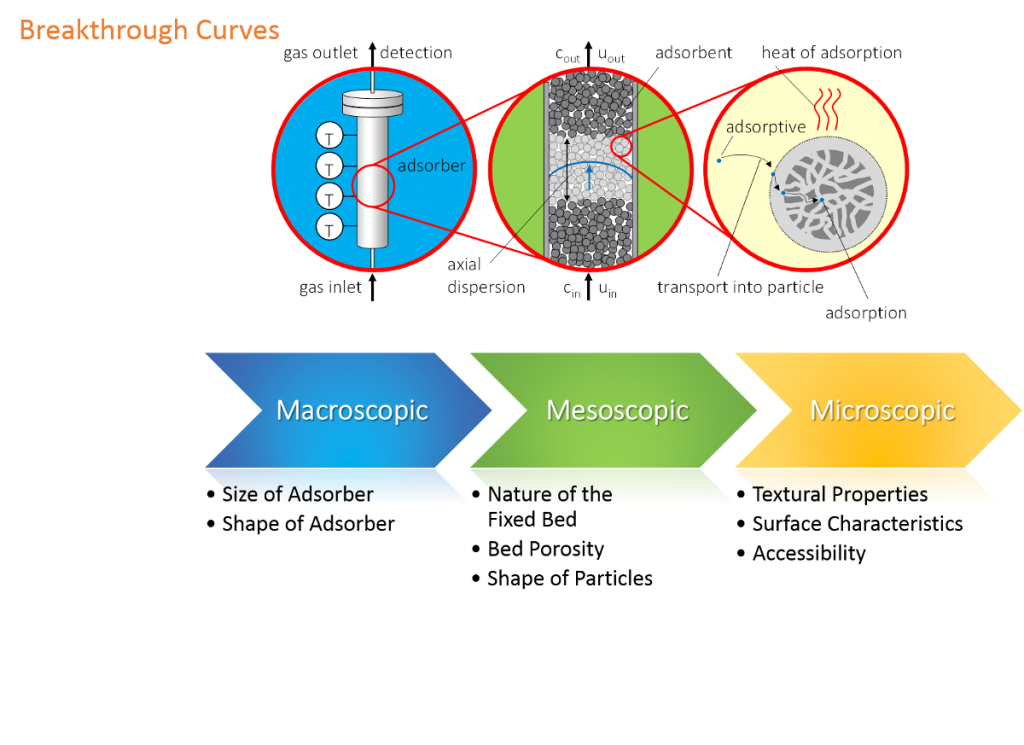

In order to minutely project technical adsorption processes, a representative selection of sample as well as an authentic representation of the flow field is required within the reactor bed.

The standard column of the mixSorb L with a volume of roughly 100ml and an internal diameter of 3cm has been modelled precisely towards these characteristics. The robust construction from stainless steel allows for experiments at temperatures up to 450°C and pressures of up to 10bar. Four Pt-100 thermo-couples positioned equidistantly along the reactors columns central vertical axis and allows for high resolution recording of temperature profiles within the reactor bed. Up to four internal mass-flow controllers allow for the arbitrary composition as well as streaming speed of gas mixtures. The detection and composition of gases and mixtures is carried out by an internal thermal conductivity detector or an additional mass spectrometer. Reversion of the flow direction within the column allows for in-detail studies of desorption processes in technical adsorbents. This allows for the investigation of regenerative capabilities as well as cyclic durability of technical adsorbents while at the same time allowing for the simulation and investigation of complex pressure swing adsorption processes (PSA).

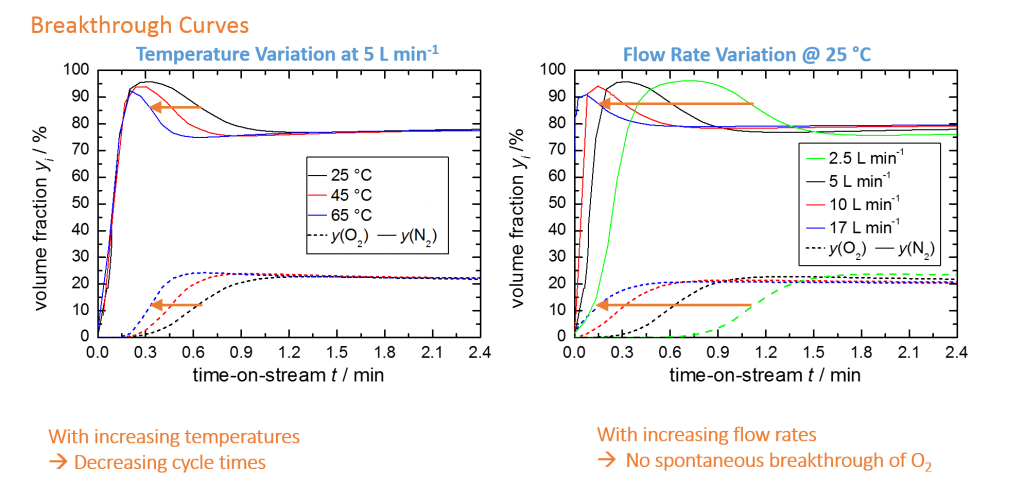

ExampleThe following scheme exemplifies the possibilities of the mixSorb L for investigating the characteristics of practical relevance within the separation of air on a carbon-based molecular sieve. The influence of temperature on the cycling time of the adsorber as well as the breakthrough speed of oxygen was investigated. These methods require the mixSorb-software mixSorb Manager, which handles dosing, measurement and data recording and reduction fully automated.

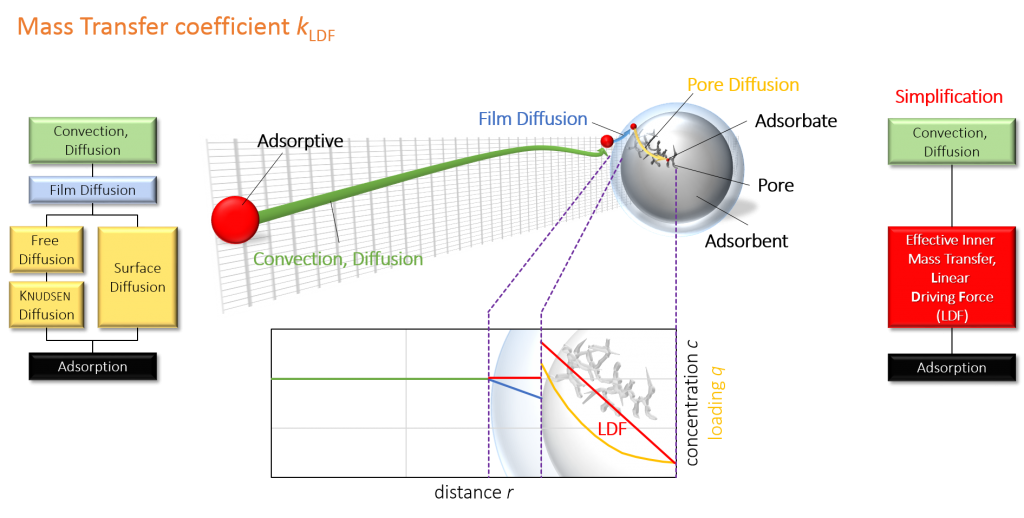

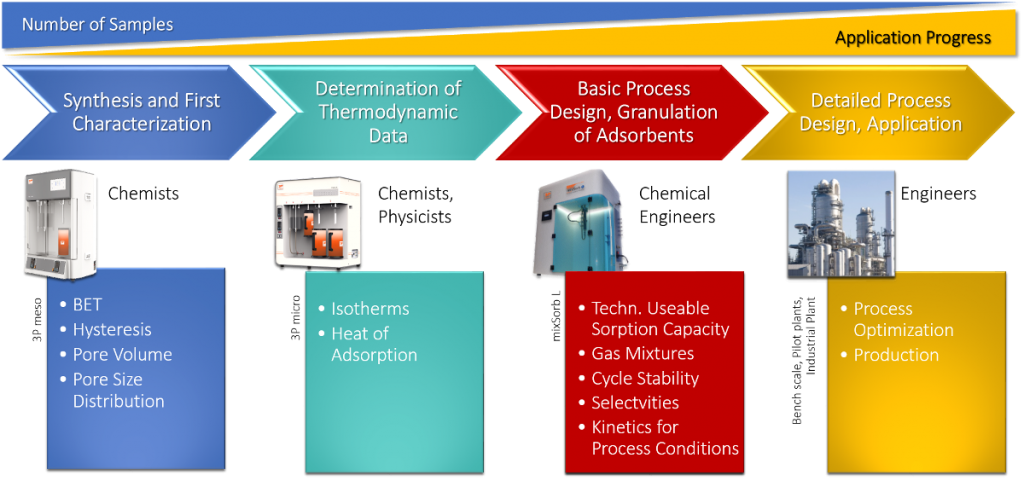

Furthermore, the mixSorb L comes with the simulation software 3P-Sim, which is an extraordinary tool for comparing experimental and theoretical data and calculating the experimental effort required for certain tasks by calculating gas mixture data from pure gas isotherms. The figure below showcases how diffusion parameters are merged into the linear driving force (LDF-) factor and below that, how fitting of the mass transfer coefficient kLDF describes experimental curves (both breakthrough and temperature curve) in the software simulation.