Mercury Scientific

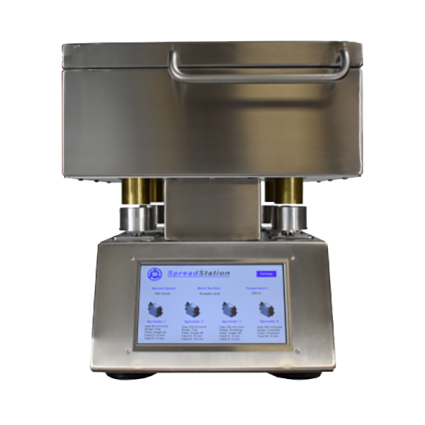

SpreadStation

Powder Spreadability Analyser

- Fast analysis time

- Programmable speed – 10 to 300 mm/s

- Temperature to 250C

The SpreadStation Powder Spreadability Analyser measures the spreadability of powders by actually spreading powders in a layer and then analysing the properties of the layer.

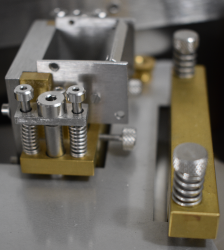

Powder is loaded into a spreading device that includes a feeder and a spreading plate. The spreading device rests on a build plate and has an adjustable gap at the bottom to control the powder layer thickness. The build plate is rotated to create linear motion between the spreading device and the build plate. This linear motion spreads the powder in a layer on the build plate.

Images of the created layer are captured and the thickness of the layer is measured using a laser distance sensor. The layer is then removed from the build plate by a scraping blade and is weighed.

The SpreadStation can be equipped with up to four spreaders and the build plate can be a solid plate or a powder bed. Spreading speed is programmable from 1 to 300 mm/s. Spreading layer thickness can be set from 20 micrometers to 2 millimeters. The build area can be heated to 250C.

-

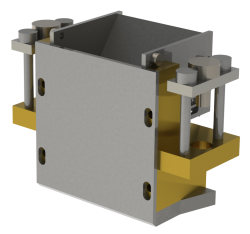

Spreaders

The SpreadStation powder spreadability analyser can be equipped with up to four powder spreading assemblies. Each spreading assembly is set up with a powder feeding system and a powder spreading plate. The feeders and spreading plates can be changed quickly to study different printer parameters and simulate different printer feeding and spreading systems. The spreadering assemblies are removed from the SpreadStation for cleaning between samples. This requires approximately 30 seconds.

Powder Feeders

Angle Feeder

The angle feeder allows the feeding angle of the sample powder to be adjusted as well as the gap at the bottom of the feeder.

Straight Feeder

The straight feeder allows the feeding width and the feeding gap from the sample powder to be adjusted.

Pressure Feeder

The pressure feeder allows the pressure on the top of the sample powder to be adjusted as well as the feeding width and feeding gap.

The powder feeders deliver sample powder to the spreading zone of the spreading assembly. The feeder can be removed without tools for cleaning and quick changes. The gap that the powder must flow through to reach the spreading zone can be adjusted for all feeders. The height of the exit of the feeder can also be adjusted.

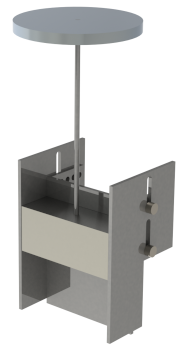

Powder Spreaders

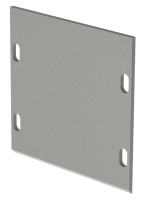

Flat Spreading Plate

The flat spreading plate has a flat bottom and can be rigid or flexible. The standard plate is made of polished stainless steel but many optional materials are available.

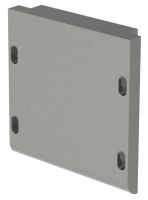

Round Spreading Plate

The round spreading plate has a round profile at the bottom.

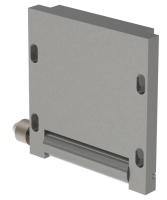

Rotating Roller Plate

The rotating roller plate uses a rotating roller to spread the test powder. The rotating direction and rotation speed is controlled by software.

The powder spreaders determine how the powder layer is formed when the powder is being spread. The spreading gap (leveling height) is set when installing the spreader on the spreading assembly.

-

Measurements

Layers created by the SpreadStation are analysed using three independent measuring systems and produce three independent sets of data. The measuring systems are: 1) weighting system; 2) laser triangulation distance system; and imaging system.

Weighting System for the SpreadStation Powder Spreadability Analyser

The weighting system measures the mass of powder being spread by the SpreadStation over time. The weighting system uses load cells to measure the powder mass and 24 bit A to D converters to digitize the load cell readings.

Weighting System Data:

Spreading Efficiency:

The spreading efficiency is the ratio of the spreading density to the material density. A spreading efficiency of 100% means the spread layer is equivalent to a solid layer of material while a spreading efficiency of 0% means there is no powder in the layer.

Spreading Density:

The density of the layer of the powder, units grams/cm3

Spreading Rate:

The mass of powder exiting the spreader over time, units grams/cm

Spreading Uniformity:

The uniformity of the layer density from the start of the test to the end of the test, units %

Laser Triangulation System

The laser triangulation system measures the thickness of the powder layer created by the SpreadStation.

Laser Triangulation System Data:

Layer thickness:

The thickness of the powder layer measured over time, units micrometres

Layer Thickness Uniformity:

The uniformity of the powder layer thickness, units %

Imaging System:

The imaging system consists of digital cameras and LED lighting that collect images of the powder layers created by the SpreadStation. Image analysis software is then used to extract information about the layer quality.

Imaging System Data:

Area Coverage:

The area coverage is the ratio of the area in the image covered by powder to the total area of the image, units %

Channel Detection:

The image analysis software determines if there are any channels is the powder layer and if so the width of the channel, units % channels, width millimetres

Wave Detection:

The image analysis software determines if there are any waves in the powder layer and their widths, units % waves, width millimetres

-

Sample Data

Spread Speed

Spread Efficiency

Layer Density

Spread Rate

Layer Thickness

50 mm/s 49.3% 3.95 g/cm3 206 mg/cm 158 um 100 mm/s 38.3% 3.06 g/cm3 157 mg/cm 117 um 150 mm/s 31.4% 2.51 g/cm3 129 mg/cm 100 um 200 mm/s 22.8% 1.83 g/cm3 94 mg/cm 72 um

50 mm/s

150 mm/s

100 mm/s

200 mm/s

-

Applications

-

Technical Specs

Spreading Rate10-300 mm/sec

Levelling Height20-2000 um

Build PlateSolid or powder bed

Sample Size5-25 cm3

TemperatureAmbient to 250C

TravelUnlimited (typical 100 cm)

Simultaneous layers4

Analysis time2 minutes typical

Not sure if it’s the right instrument?

No worries, send us a sample and we will test it for you

Send a sample-

Outstanding service

I have been using Meritics for a number of years and they always provide outstanding service and support.

They have a rapid response turnarounds and are very knowledgeable of the techniques and products they provide.LeanneB-375

-

Good service, very helpful

We use Meritics for the PM service and installation of all our FlowCams . Megan has been coming to our site for a number of years. She is very efficient in her work, but most of all Megan is very helpful. We have had issues with one of instruments after the install and Megan did her utmost to try and solve it while on site, even though it wasn’t solved Megan has been in contact with the supplier of the instrument to try and solve this problem for us.

SophieH-2201

-

Job done in a friendly manner

Booking engineer visits is always easy. David Lowe, Meritics engineer is always very friendly.

ThierryN

-

Service/calibration visit

Excellent service, arrived on time, polite, friendly and informative.

NathamM-270

-

5 Stars

Excellent service from an excellent company. Would recommend them to anyone.

BarryH-480

-

Good Service

David, our service engineer as usual was good at communicating and setting up the recent service appointment, he arrived on time, did the service promptly and informed me of any problems. Friendly and helpful

TomA-446

-

Superb and prompt service

I have used this company through the laboratory I work for frequently. We specialise in soil analysis, and Meritics were chosen as they have extensive knowledge of the instruments we use. We have several laser particle diffraction analysers with a service contract, and service is always very prompt and meticulous….

JamesG-2483

-

Good experience over two years

Meritics have covered the annual servicing of our Multisizer 4e instrument since we purchased it from them just over two years ago. The application scientist who performed the servicing was friendly, knowledgeable, and extremely helpful, happily answering a barrage of questions about how best to use and maintain the instrument. All my interactions with Meritics staff have been positive. I would happily recommend them.

RajG-62

-

Fully committed to customer service

Service second to none, both units serviced and all questions answers by engineer while on site.

RichardA-786

-

Highly recommend Meritics for equipment purchases and aftercare services

After owning one of our instruments for over 8 Years which was purchased from Meritics, it suffered its first breakdown. Upon contacting Meritics, I was instantly put through to an engineer who was very helpful. Upon inspection of the manual, it was decided that it would be more cost effective to have a Meritics engineer visit. The Meritics staff were very communicative and kept me up to date.

-

Excellent Service

Lovely, friendly and extremely helpful. David and his team are always on call with advise and are very easy to work with and are always happy to help.

NaomiT-64

-

Service of lab equipment

Excellent service. Friendly and professional service was provided in a timely manner to the expected standard.

NathanM-270

-

Excellent

Excellent communication. Updates given well in advance. Very polite staff and engineers.

NathanM-270

-

Multisizer 4e install at pharmaceutical company

2 people helped with the install of a Multisizer 4e. They were both very professional and friendly, answering any questions that I had. The installation was quick and the attention to good documentation practice was exceptional.

Chloel-9

-

Service of Beckman Coulter instruments

Always a pleasure to welcome the Meritics service engineer, who is knowledgeable, personable and extremely competent.

NeilT-394

-

Professional

Friendly and collaborative staff, provided a very good service.

SamK-403

-

Professional, Customer-oriented, fast service

We had issues with one of the aperture tubes provided by Meritics on a Friday afternoon, while very pressed for a review deadline. Meritics handled our inquiries very fast and professionally and helped us out by shipping us their spare tube to use in the mean time free of charge, while we waited for our new tube to arrive. Communication was very pleasant.

VeerleB

-

Very helpful and prompt

I emailed for some technical help and also to get some spares and both the engineer (David) and purchasing (Sophie) were very prompt to respond and helpful. We do have a service contract but I appreciated being able to email the engineer directly.

AlexH-474

-

Excellent Service

Used Meritics to conduct particle size distribution by laser diffraction. Service as last time, is very quick, well priced and professional.

I would highly recommend

GavinR-101

-

Excellent and Friendly Service

Always a pleasure to deal with the people at Meritics Ltd. They understand the importance of our work and the fact that our research projects have deadlines that need to be met. Consequently, problems are dealt with very quickly and professionally and they are willing to go that one step further to make sure their supply chain problems don’t become our problems. Thank you to the team for their support. It is greatly appreciated.

JanetH-255