Porometer

Porolux Revo

Porous Materials Analyser

- Gas-liquid technology with patent pending MP2 technology

- The most accurate pore size results combined with high resolution

- For pore sizes down to 13nm

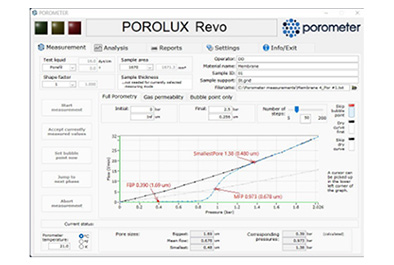

The POROLUX™ Revo, the successor of the POROLUX™ 1000, is the revolution in porometry for porous materials. Setting the bar in step stability method with our patent pending MP² (Multistage Pressure Process) technology, the POROLUX™ Revo delivers the most accurate and reproducible pore size measurements, in the highest resolution.

Measuring porous materials with the Porolux Revo provides accurate and detailed insights into pore size and distribution. This advanced analyser utilises cutting-edge technology to assess porosity, including pore volume and surface area. Ideal for materials such as membranes, filters, and powders, the Porolux Revo enhances quality control and research by delivering reliable, high-resolution data. Its user-friendly interface and precise measurements make it an essential tool for thorough porous materials analysis.

-

Key Features

Patent pending MP² technology

MP² stands for Multistage Pressure Process. This innovative technology ensures a smooth pressure increase during the measurement and speeds up the process of reaching flow and pressure stability.

This advanced pressure built-up process makes it possible to do the measurements with smaller, and perfectly uniform pressure steps, leading to the most accurate and reproducible pore size results. Additionally, the technology makes it possible to record more data points in the pore opening region, resulting in more detailed pore size distribution curves.

Step stability methodThe POROLUX™ Revo detects the opening of a pore at a certain pressure and waits until all pores of the same diameter are completely opened before accepting the data point. This method results in a very accurate pore size measurement and allows to calculate the true pore size distribution.

Additionally, the instrument can determine the bubble point in three different ways (largest pore according to ASTM F-316-03), a very unique feature in the market of porometry.

Next to that, results on mean flow pore size, smallest pore, pore size distribution, cumulative flow distribution & gas permeability are reported. With our enhanced mathematical model, we can also obtain additional results such as total pore number and total pore area.

Very intuitive and easy to use software

Not only is the fully integrated software powerful and comprehensive, it is also very intuitive and easy to use.

By allowing to change many parameters with a click of the mouse, the software enables its many users to tune the measurement to their exact needs. Additionally, the software, with built-in intelligence, gives the user access to many advanced functions, such as the re-evaluation function and the observation window.

Last but not least, the POROLUX™ Revo software comes with a very advanced curve smoothing and fitting function.

Straightforward and presentable output

With one click of the button, results are exported in word, excel or pdf. The Porometer software makes it very easy to present multiple measurements next to each other, allowing for a straightforward comparison between different filter media.

Thanks to the adjustable scales, graphs such as wet and dry curve and pore size distribution are presented in a very clear and sophisticated manner.

-

Technical Specs

POROLUX™ Revo Technique Gas-liquid porometry Measurement method Pressure step/stability with patent pending MP² technology Max pressure 35 bar/500 psi Min pore (1) 13 nm Max pore (1) 500 µm Max flow 200 l/min Bubble point BP dPL, BP x-ml, BP pCF (*) Dimensions (DxWxH) 530x530x755 mm Weight 70 kg (1) Depending on the wetting liquid.

(*) BP dPL is the bubble point measured as a deviation from the linearity of a user-defined pressure increase. BP x-ml is the bubble point measured at a user-defined flow rate. BP pCF is the bubble point measured as a user-defined percentage of the cumulative flow.

-

Accessories

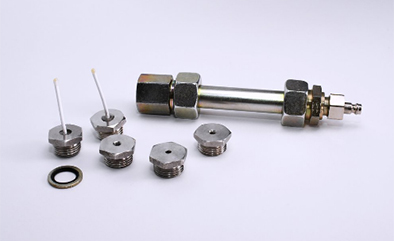

Universal sample holder 3 in 1

Sample holder 3 diameters in 1 (13, 25 and 47 mm).

Hollow fibre sample holder

Specially designed sample holder for hollow fibres, including 5 sealant rings.

Sample holder of 25 mm diameter for thicker samples

External sample holder for samples of thickness up to 10 mm.

Customer specific solutions

Porometer can also create customer specific sample holders to meet special requirements, such as measuring thick samples, samples with larger diameters, working with assembled filter setups, etc.

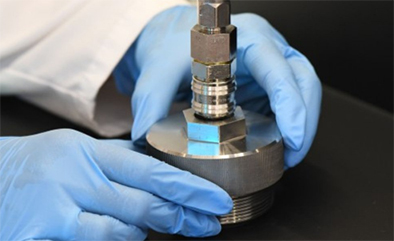

Advanced liquid permeability

The liquid permeability extension performs a fully automatic measurement of the flow of liquid through a membrane or filter at a predefined pressure. The liquid is then collected in a receptacle and the weight data – which is recorded by the balance – is automatically transferred to the operating software, which calculates the liquid permeability.

This method is user friendly, very accurate and is strongly recommended when a lot of liquid permeability measurements are envisaged. The advanced liquid permeability extension consists of a hardware extension – including the liquid tank, an external sample holder, a balance and all tubing and connections, as well as a software extension.

-

Applications

Not sure if it’s the right instrument?

No worries, send us a sample and we will test it for you

Send a sample-

Outstanding service

I have been using Meritics for a number of years and they always provide outstanding service and support.

They have a rapid response turnarounds and are very knowledgeable of the techniques and products they provide.LeanneB-375

-

Good service, very helpful

We use Meritics for the PM service and installation of all our FlowCams . Megan has been coming to our site for a number of years. She is very efficient in her work, but most of all Megan is very helpful. We have had issues with one of instruments after the install and Megan did her utmost to try and solve it while on site, even though it wasn’t solved Megan has been in contact with the supplier of the instrument to try and solve this problem for us.

SophieH-2201

-

Job done in a friendly manner

Booking engineer visits is always easy. David Lowe, Meritics engineer is always very friendly.

ThierryN

-

Service/calibration visit

Excellent service, arrived on time, polite, friendly and informative.

NathamM-270

-

5 Stars

Excellent service from an excellent company. Would recommend them to anyone.

BarryH-480

-

Good Service

David, our service engineer as usual was good at communicating and setting up the recent service appointment, he arrived on time, did the service promptly and informed me of any problems. Friendly and helpful

TomA-446

-

Superb and prompt service

I have used this company through the laboratory I work for frequently. We specialise in soil analysis, and Meritics were chosen as they have extensive knowledge of the instruments we use. We have several laser particle diffraction analysers with a service contract, and service is always very prompt and meticulous….

JamesG-2483

-

Good experience over two years

Meritics have covered the annual servicing of our Multisizer 4e instrument since we purchased it from them just over two years ago. The application scientist who performed the servicing was friendly, knowledgeable, and extremely helpful, happily answering a barrage of questions about how best to use and maintain the instrument. All my interactions with Meritics staff have been positive. I would happily recommend them.

RajG-62

-

Fully committed to customer service

Service second to none, both units serviced and all questions answers by engineer while on site.

RichardA-786

-

Highly recommend Meritics for equipment purchases and aftercare services

After owning one of our instruments for over 8 Years which was purchased from Meritics, it suffered its first breakdown. Upon contacting Meritics, I was instantly put through to an engineer who was very helpful. Upon inspection of the manual, it was decided that it would be more cost effective to have a Meritics engineer visit. The Meritics staff were very communicative and kept me up to date.

-

Excellent Service

Lovely, friendly and extremely helpful. David and his team are always on call with advise and are very easy to work with and are always happy to help.

NaomiT-64

-

Service of lab equipment

Excellent service. Friendly and professional service was provided in a timely manner to the expected standard.

NathanM-270

-

Excellent

Excellent communication. Updates given well in advance. Very polite staff and engineers.

NathanM-270

-

Multisizer 4e install at pharmaceutical company

2 people helped with the install of a Multisizer 4e. They were both very professional and friendly, answering any questions that I had. The installation was quick and the attention to good documentation practice was exceptional.

Chloel-9

-

Service of Beckman Coulter instruments

Always a pleasure to welcome the Meritics service engineer, who is knowledgeable, personable and extremely competent.

NeilT-394

-

Professional

Friendly and collaborative staff, provided a very good service.

SamK-403

-

Professional, Customer-oriented, fast service

We had issues with one of the aperture tubes provided by Meritics on a Friday afternoon, while very pressed for a review deadline. Meritics handled our inquiries very fast and professionally and helped us out by shipping us their spare tube to use in the mean time free of charge, while we waited for our new tube to arrive. Communication was very pleasant.

VeerleB

-

Very helpful and prompt

I emailed for some technical help and also to get some spares and both the engineer (David) and purchasing (Sophie) were very prompt to respond and helpful. We do have a service contract but I appreciated being able to email the engineer directly.

AlexH-474

-

Excellent Service

Used Meritics to conduct particle size distribution by laser diffraction. Service as last time, is very quick, well priced and professional.

I would highly recommend

GavinR-101

-

Excellent and Friendly Service

Always a pleasure to deal with the people at Meritics Ltd. They understand the importance of our work and the fact that our research projects have deadlines that need to be met. Consequently, problems are dealt with very quickly and professionally and they are willing to go that one step further to make sure their supply chain problems don’t become our problems. Thank you to the team for their support. It is greatly appreciated.

JanetH-255