Porometer

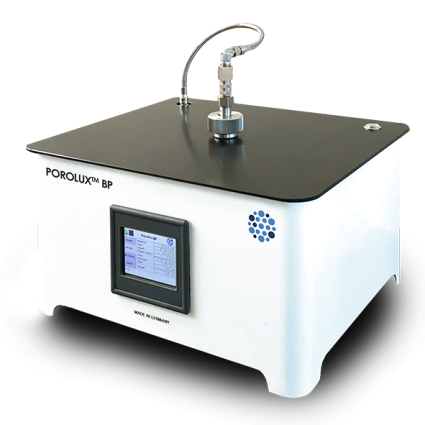

Porolux BP

Bubble Point Tester

- Bubble point measurement only

- Quick and easy determination of the bubble point

- For pore size analysis down to 0.1 µm

The POROLUX™ BP is a bubble point tester, used to measure the largest pore size – often referred to as ‘bubble point (BP)’ – in media that are used for filtration and separation applications.

The Porolux BP excels in pore size analysis by precisely determining the largest pore size through bubble point measurement. This pore size analysis technique involves assessing the pressure at which gas displaces liquid from the largest pores, providing accurate data on pore structure. Ideal for characterising materials like membranes, filters, and powders, the Porolux BP ensures reliable results for both research and industrial applications. With its advanced technology, the Porolux BP delivers detailed pore size analysis, enhancing material performance evaluation and quality control processes. This makes it an essential tool for accurate and comprehensive pore size analysis.

-

Key Features

Quick, accurate and reproducible results

POROLUX™ BP delivers quick and accurate results of the first bubble point in the pressure range from 0 bar (0 psi) up to 5 bar (75 psi) and detects pores from ca. 300 μm down to 0.13 μm.

Thanks to its simplified operation, the POROLUX™ BP provides highly reproducible results for both the BP x-ml and BP dPL bubble point. This makes the POROLUX™ BP a clear choice for quality control and/or R&D in many companies producing filtration and separation media.

Full automatic detection of Bubble point

The ASTM F-316-03 standard defines the BP as ‘the pressure at which the first continuous stream of gas bubbles is detected’.

While this is based on visual detection, the POROLUX™ BP now offers a fully automated way to determine the bubble point.

Detection of both BP x-ml and BP dPL

The POROLUX™ BP can detect both the BP x-ml and BP dPL bubble point. The BP dPL is the bubble point measured as a deviation from the linearity of a user-defined pressure increase, while BP x-ml is the bubble point measured at a user-defined flow rate.

It is evident that the dPL bubble point generates highly reproducible measurements with correspondingly low scatter. The dPL bubble point is typically very accurate. However, at high pressures, the dPL bubble point can be falsely created by turbulence. In this case, we advise using the BP x-ml.

The instrument determines the bubble point by using digital pressure and flow sensors. In this way, the chance of a human error or the subjective operator’s opinion is eliminated. This helps to standardize the filter media testing in terms of consistency and reliability.

-

Technical Specs

Max pressure5 bar/75 psi

Min pore (1)0,13 µm

Max pore (1)300 µm

Max flow150ml/min

Bubble pointBP x-ml and BP dPL (*)

Dimensions350x400x350 mm

Weight10 kg

(1) Depending on the wetting liquid.

(*) BP x-ml is the bubble point measured at a user-defined flow rate. BP dPL is the bubble point measured as a deviation from the linearity of a user-defined pressure increase.

-

Applications

Not sure if it’s the right instrument?

No worries, send us a sample and we will test it for you

Send a sample-

Outstanding service

I have been using Meritics for a number of years and they always provide outstanding service and support.

They have a rapid response turnarounds and are very knowledgeable of the techniques and products they provide.LeanneB-375

-

Good service, very helpful

We use Meritics for the PM service and installation of all our FlowCams . Megan has been coming to our site for a number of years. She is very efficient in her work, but most of all Megan is very helpful. We have had issues with one of instruments after the install and Megan did her utmost to try and solve it while on site, even though it wasn’t solved Megan has been in contact with the supplier of the instrument to try and solve this problem for us.

SophieH-2201

-

Job done in a friendly manner

Booking engineer visits is always easy. David Lowe, Meritics engineer is always very friendly.

ThierryN

-

Service/calibration visit

Excellent service, arrived on time, polite, friendly and informative.

NathamM-270

-

5 Stars

Excellent service from an excellent company. Would recommend them to anyone.

BarryH-480

-

Good Service

David, our service engineer as usual was good at communicating and setting up the recent service appointment, he arrived on time, did the service promptly and informed me of any problems. Friendly and helpful

TomA-446

-

Superb and prompt service

I have used this company through the laboratory I work for frequently. We specialise in soil analysis, and Meritics were chosen as they have extensive knowledge of the instruments we use. We have several laser particle diffraction analysers with a service contract, and service is always very prompt and meticulous….

JamesG-2483

-

Good experience over two years

Meritics have covered the annual servicing of our Multisizer 4e instrument since we purchased it from them just over two years ago. The application scientist who performed the servicing was friendly, knowledgeable, and extremely helpful, happily answering a barrage of questions about how best to use and maintain the instrument. All my interactions with Meritics staff have been positive. I would happily recommend them.

RajG-62

-

Fully committed to customer service

Service second to none, both units serviced and all questions answers by engineer while on site.

RichardA-786

-

Highly recommend Meritics for equipment purchases and aftercare services

After owning one of our instruments for over 8 Years which was purchased from Meritics, it suffered its first breakdown. Upon contacting Meritics, I was instantly put through to an engineer who was very helpful. Upon inspection of the manual, it was decided that it would be more cost effective to have a Meritics engineer visit. The Meritics staff were very communicative and kept me up to date.

-

Excellent Service

Lovely, friendly and extremely helpful. David and his team are always on call with advise and are very easy to work with and are always happy to help.

NaomiT-64

-

Service of lab equipment

Excellent service. Friendly and professional service was provided in a timely manner to the expected standard.

NathanM-270

-

Excellent

Excellent communication. Updates given well in advance. Very polite staff and engineers.

NathanM-270

-

Multisizer 4e install at pharmaceutical company

2 people helped with the install of a Multisizer 4e. They were both very professional and friendly, answering any questions that I had. The installation was quick and the attention to good documentation practice was exceptional.

Chloel-9

-

Service of Beckman Coulter instruments

Always a pleasure to welcome the Meritics service engineer, who is knowledgeable, personable and extremely competent.

NeilT-394

-

Professional

Friendly and collaborative staff, provided a very good service.

SamK-403

-

Professional, Customer-oriented, fast service

We had issues with one of the aperture tubes provided by Meritics on a Friday afternoon, while very pressed for a review deadline. Meritics handled our inquiries very fast and professionally and helped us out by shipping us their spare tube to use in the mean time free of charge, while we waited for our new tube to arrive. Communication was very pleasant.

VeerleB

-

Very helpful and prompt

I emailed for some technical help and also to get some spares and both the engineer (David) and purchasing (Sophie) were very prompt to respond and helpful. We do have a service contract but I appreciated being able to email the engineer directly.

AlexH-474

-

Excellent Service

Used Meritics to conduct particle size distribution by laser diffraction. Service as last time, is very quick, well priced and professional.

I would highly recommend

GavinR-101

-

Excellent and Friendly Service

Always a pleasure to deal with the people at Meritics Ltd. They understand the importance of our work and the fact that our research projects have deadlines that need to be met. Consequently, problems are dealt with very quickly and professionally and they are willing to go that one step further to make sure their supply chain problems don’t become our problems. Thank you to the team for their support. It is greatly appreciated.

JanetH-255