Mercury Scientific

Evolution

Powder Flow Tester

- Easy to understand powder flow analysis

- Simple analysis procedure

- 3 minute test time

- Very affordablw

The patented EVOLUTION Powder Tester measures a powder or granular material’s response to environmental stresses. The major stress on a material is pressure. The EPT measures a material’s response to pressure by applying pressure to the material and then measuring its resulting strength. This strength is known as the unconfined yield strength. If a powder is to flow, the force making the powder move must be greater than the unconfined yield strength.

The unconfined yield strength can be measured at one pressure or at many pressures to create what is called a flow function. The flow function presents the material’s gain in strength as more pressure is applied to it.

For most powders and granular materials, the longer the material is exposed to pressure, the higher the unconfined yield strength becomes. Therefore, for powders and granular material that are stored for any length of time, it is essential to study the effects of pressure over time. This is called time unconfined yield strength. In addition, a time flow function can be created. With the EPT, time tests are easy and inexpensive to perform. Time cells consist of sample cells and weights that allow a material to be subjected to various pressures over long periods of time. In addition to pressure, temperature and humidity can affect a material’s strength over time. The EPT time cells are designed so that they can be easily placed in ovens and humidity chambers to study their effects on materials in storage situations. Time is the unmeasured parameter in flow property tests. The reason? Analysis cells for many flow measurement cells are very expensive and do not include the means of applying pressure over long periods.

The EVOLUTION Powder Tester measures the unconfined yield strength and time unconfined yield strength for less than the cost of having 3 or 4 samples tested by independent laboratories.

-

Unconfined Yield Strength

The unconfined yield strength of a material is the force or stress required to deform or break a material when it is not confined by a container (free unstressed surface). From a testing perspective, the unconfined yield strength can be expressed as the stress required to fail or fracture a consolidated mass of material to initialize flow. The force used to consolidate the mass of material is called the Major Consolidation Stress.

The unconfined yield strength is very important in studying the flowability of materials. The reason is that the force required to get a powder or granular material to flow is directly related to the unconfined yield strength. In simple terms, the powder or granular material will flow if the force acting on it is greater than the unconfined yield strength of the material. A flow factor (ff) is calculated by dividing the major consolidation stress by the unconfined yield strength. This flow factor is used to classify materials into categories such as non-flowing (ff < 1), very cohesive (1 < ff < 2), cohesive ( 2 < ff < 4), easy flowing (4 < ff < 10), and free flowing (ff > 10).

The EVOLUTION Powder Tester measures the unconfined yield strength of a material in a two stage process. First, the material is loaded into a sample cell and compressed by vertical pressure.

The EVOLUTION Powder Tester measures the unconfined yield strength of a material by applying pressure to a sample over time. First, the material is loaded into a sample cell.

Then, a predefined pressure is applied to the top of the sample to consolidate it. The pressure can be applied on the instrument or by using weights.

Then, a predefined pressure is applied to the top of the sample to consolidate it. The pressure can be applied on the instrument or by using weights. After the material is compressed, the sample is then automatically removed from the sample cell and force is applied to the top of the sample to break or fail the material. The break cap contains the material for easy clean-up. The maximum force recorded when breaking the material is the unconfined yield strength.

After the material is compressed, the sample is then automatically removed from the sample cell and force is applied to the top of the sample to break or fail the material. The break cap contains the material for easy clean-up. The maximum force recorded when breaking the material is the unconfined yield strength.

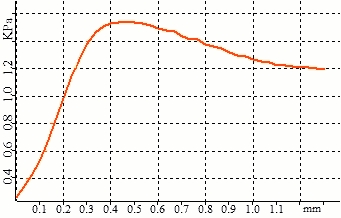

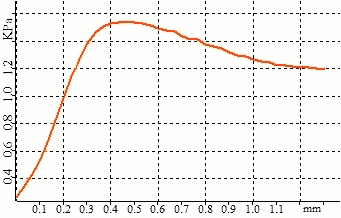

Break Stress Versus Break Strain

The unconfined yield strength of a material typically increases as the pressure on the material increases. A plot of the unconfined yield strength versus the major consolidation stress is called a flow function. The flow function presents the powder or granular material’s response to pressure. Flow functions are very useful for predicting flowability because the forces acting on a material change at various points in a typical process. Therefore, it is important to know how the material responds to these forces.

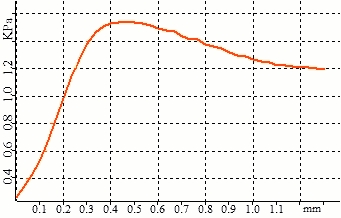

Flow Function

Flow functions are also very useful for comparing the flow behavior of formulations and blends. As can be seen below, at low pressure the two samples are similar but at higher pressures their behavior diverges dramatically.

Flow Function Overlay

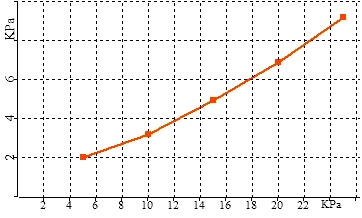

In addition, the unconfined yield strength of a powder or granular material typically increases the longer it is under the major consolidation stress. For this reason, it is very important to measure the time unconfined yield strength for materials that will be stored for any length of time. A plot of the time unconfined yield strength versus the major consolidation stress is typically called the time flow function.

-

Time UYS

The unconfined yield strength of a powder or granular material typically increases the longer it is under the major consolidation stress. For this reason, it is very important to measure the time unconfined yield strength for materials that will be stored for any length of time.

The EVOLUTION Powder Tester measures the time unconfined yield strength of a material by applying pressure to a sample over time. First, the material is loaded into a sample cell.

Then, the sample is compressed by vertical pressure applied from a weight or weights. Each weight delivers 2.5 KPa.

The material is then left for hours or days under controlled conditions to allow the major consolidation stress to act on the material for a specific period of time. These controlled conditions include temperature and humidity. The sample cells are small enough and stable enough to be put in ovens and humidity chambers or simply on laboratory shelves.

After the material is compressed, the sample is then automatically removed from the sample cell and force is applied to the top of the sample to break or fail the material. The maximum force recorded when breaking the material is the unconfined yield strength.

A plot of the time unconfined yield strength versus the major consolidation stress is typically called the time flow function. The time flow function is measured by applying a different number of weights to different sample cells. Each Evolution cell weight corresponds to 5 KPa.

Typically powders and granular materials gain strength as they are exposed to major consolidation stress over time.

-

Quality Control

Powder flow testers can be difficult to use in quality control or plant settings. The reason is that many testers are difficult to load, time consuming to use, not very precise, and expensive. Not the EVOLUTION Powder Tester. The EPT was designed from the start to be fast, easy to use, precise and inexpensive. In addition, due to its simple design, the EPT requires no routine maintenance. In short, the perfect quality control instrument for measuring flow behavior.

For QC measurements, the EVOLUTION Powder Tester can measure the unconfined yield strength of a sample at one pressure in 3 minutes. Loading the sample into the analysis cell is easy as it is a simple cup. A filling tool is used to overfill the cup and then scrape the top to get the correct amount of sample in the cup. The sample cup it then put on the EPT with the compression top to compress the sample. After compression, the compression top is replaced by the break cap and the unconfined yield strength is measured.

Measuring the unconfined yield strength of a material can provide information as to whether a material is on specification and will handle as expected. Because the test is fast, all shipments or production lots of material can be tested before they are transferred to processes and can create problems.

-

Analysis Cells

There are two options for EVOLUTION Powder Tester analysis cells along with time test options for each.

- Small UYS Cell – The patented Small UYS Cell is a test cell for measuring the unconfined yield strength of cohesive or compressible powder samples. The test volume is 5 cm3.

- Standard UYS Cell – The patent pending Large UYS Cell is a test cell for measuring the unconfined yield strength of cohesive granular materials. The test volume is 25 cm3

Time Options

The above cells are sold in sets of five with five weights to allow time tests to be measured.

-

Vs Shear

The Evolution Powder Tester is used to compare the behavior of materials under consolidated load. The only other instruments available for this type of test are powder shear testers. The Evolution was designed specifically as an alternative to shear testers for the following reasons:

1) Shear testers are slow – A typical unconfined yield strength shear test takes 45 minutes. A flow function takes hours. Aside from waiting for data, the slow test time gives the sample material time to changed due to environmental conditions i.e. moisture loss or temperature change. The Evolution requires 3 minutes for an unconfined yield strength test and 15 minutes for a 5 point flow function.

2) Shear testers subject the sample to mechanical stress that causes sample breakdown – The original shear testers used fresh material for every point on the yield locus to ensure that the repeated testing did not change the material. Some instruments use the same material over and over because they are impractical if fresh sample is used each time. This can cause inaccurate strength data due to attrition and prefered particle orientation in the shear zone. This may occur to different degrees in different samples. In addition, a sample should never be exposed to more than one stress level i.e. run a flow function on the same sample. In our experience this causes the flow function to be inaccurate in roughly 80 percent of tested samples. The Evolution uses fresh sample for every test.

3) Shear testers cannot control the stress level on the sample – To compare the unconfined yield strength of samples, it is essential to subject them to exactly the same conditions. This does not happen in shear testers. The major consolidation stress is controlled by the normal load and the shear forces in the sample. The normal load is controlled but the shear stress depends on the sample. This means that flow indexes calculated by shear testers are not performed at the same stress level. This can actually create artificial differences in the measurements between samples. In addition, if one sample tests faster than another, it is exposed to much less mechanical stress. With the Evolution, the stress on the sample is completely controlled and is the same for every sample tested.

4) Time tests are expensive and difficult if impossible with shear testers – Shear test cells are complex which makes them expensive. In addition, they usually have a large lid area which means large forces are needed to keep the sample under pressure for any length of time. These two factors typically preclude time measurements. Some manufacturers claim to run time test by leaving the sample in the instrument for long periods of time. However, this is not practical for two reasons: 1) the instrument cannot be used for other tests during this period; and 2) the sample is not under controlled conditions (unless the whole instrument is put in a glove box – but then temperature and humidity conditions are severely limited). The Evolution was designed for time tests with inexpensive test cells, small lid areas requiring lower forces, and standard weights included. Test time after removal from ovens or humidity chambers is 20 seconds giving the sample no time to change.

The only claim shear tester manufacturers can make against the Evolution is that they are following a standard test for powder strength measurements. However, this is not really true. There are no universally accepted methods or shear cell designs for measuring the true strength of materials. The only real claim shear tester manufacturers can make is that their instruments get the correct strength for the only recognized powder flow standard. This flow standard is BCR limestone. This limestone was a sample that was tested in a round robin method at several European powder flow laboratories using the linear shear cell. The average results of all of the laboratories has become the “standard” value. Therefore, the thinking goes, if an instrument measures the correct value for the limestone then it is accurate for every other sample. The good news is that the Evolution measures the correct values for the limestone standard under all test conditions. We are happy to provide potential customers with a complete report with this data. More good news is that it makes these measurements faster, easier, and less expensively than shear testers.

-

Applications