Introduction

Geometry can play a crucial role in the performance of fibres in

different applications. Shape factors that influence performance

include length (i.e. size of the longest dimension of the fibre), width

(i.e. size of the shortest dimension), and curl. Despite the importance

of fibre geometry, many conventional particle sizing measurements

struggle to accurately capture the morphology of these particles.

Volumetric-based particle sizing methods such as laser diffraction

and Coulter Counters assume particles exhibit spherical geometry

and only report equivalent spherical diameter (ESD) measurements.

Manual microscopy, the primary method used for measuring fibre

length and width, is low-throughput and labour-intensive to perform.

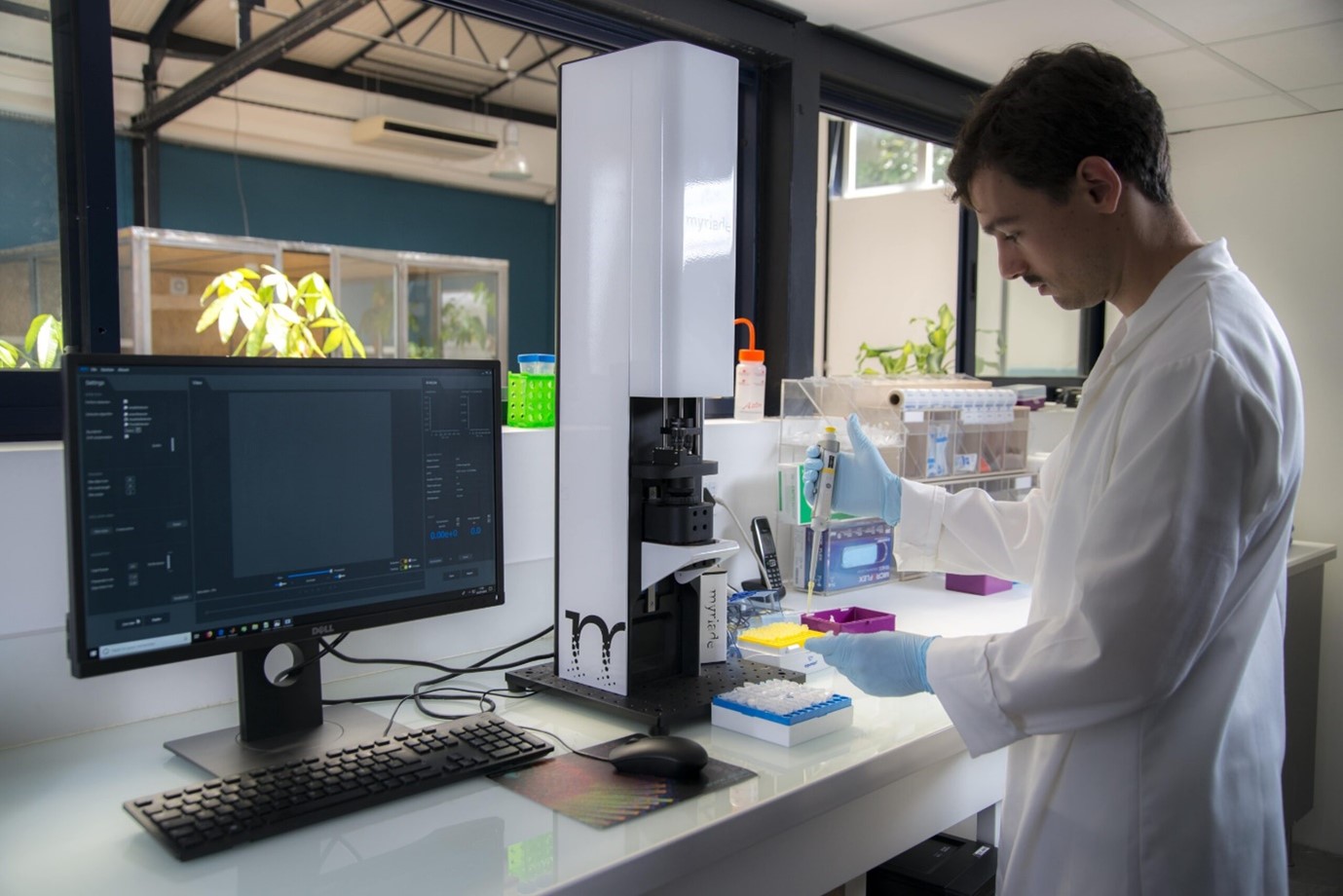

Flow imaging microscopy (FIM) instruments like FlowCam are an

automated, high-throughput alternative to manual microscopy for

fibre analysis. VisualSpreadsheet® software acquires and analyses

images of fibrils, providing automated measurements of not only

fibre length and width but also fibre straightness and curl from

particle images similar to those obtained via manual microscopy

(Figure 1). As FIM instruments capture fibre images in a flowing

fluid, this technique offers much higher throughput than manual

microscopy. These features make FlowCam an ideal instrument for

rapid, automatic fibre analysis.

Fibre measurements in VisualSpreadsheet

Most particle imaging systems use Feret measurements to determine

the length and width of particles. Feret measurements involve finding

edges on opposite sides of a particle that are parallel to each other

and measuring the distance between these edges. The shortest

Feret measurement is reported as particle width, and the longest

is reported as particle length (Figure 2). These Feret measurements

are recorded as the “Length” and “Width” parameters reported

by VisualSpreadsheet. While these measurements are accurate for

symmetric and straight particles, Feret measurements dramatically

undersize the length and oversize the width of curved particles.

VisualSpreadsheet also records Geodesic measurements of particle

lengths and widths. Geodesic measurements account for the arcing

of particles like fibres, thus providing a more accurate representation

of fibre length and width (Figure 2). In VisualSpreadsheet, these fibre

measurements are reported as geodesic length and geodesic thickness.

Figure 3 shows a comparison between these measurements for a

straight fibre and for a curved fibre. Reported values for length (Feret)

and geodesic length of the straight fibre are relatively similar, as are

those for width (Feret) and geodesic thickness. When these values

are compared for the curved fibre, the length (Feret) measurement

is much lower than the geodesic length measurement, and width is a

much larger value than the geodesic thickness measurement. While

the length (Feret) measures the long-axis distance covered by the

particle, the geodesic length factors the curvature of the particle into

its reported length and is thus more accurate. Similarly, the geodesic

thickness is more accurate as it primarily accounts for the width of the

particle and not the short-axis distance covered by the particle.

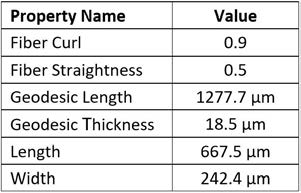

Other fibre measurements available in VisualSpreadsheet include

fiber straightness and fibre curl. Fiber straightness is the ratio

of length (Feret) to geodesic length. Higher straightness values

indicate better agreement between the Feret and geodesic length

measurements, corresponding to straighter particle geometry.

Fiber curl is calculated by dividing geodesic length by length (Feret)

and subtracting one. A particle with a fibre curl of zero is perfectly

straight and increasing curl values indicating higher degrees of

curling. Figure 4 shows fibre measurement data for a curved wood

fibre with a relatively high fibre curl value and relatively low fibre

straightness value.

Using fibre measurements to evaluate samples

In applications where fibre morphology is important for quality

control of fibrous materials, VisualSpreadsheet can be used to

build and save custom filters that automatically report counts and

concentrations of particles matching a particular specification. For

example, if fibre straightness is of concern, pre-built filters can

automatically report a percent of fibres that meet or exceed a user defined

fibre straightness threshold.

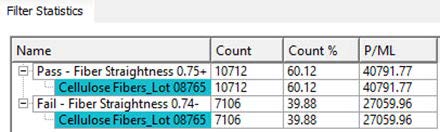

Figure 5 shows data for custom value filters created for bleached

softwood cellulose microfibrils at a specific stage of the refining

process. For this example, at least 50% of the fibres must have fibre

straightness ≥ 0.75 for a lot to pass quality control. After each lot of

fibres is analysed, the filter bins instantly populate with a percentage

of particles matching the passing criteria, allowing operators to

quickly assess whether a particular lot has passed.

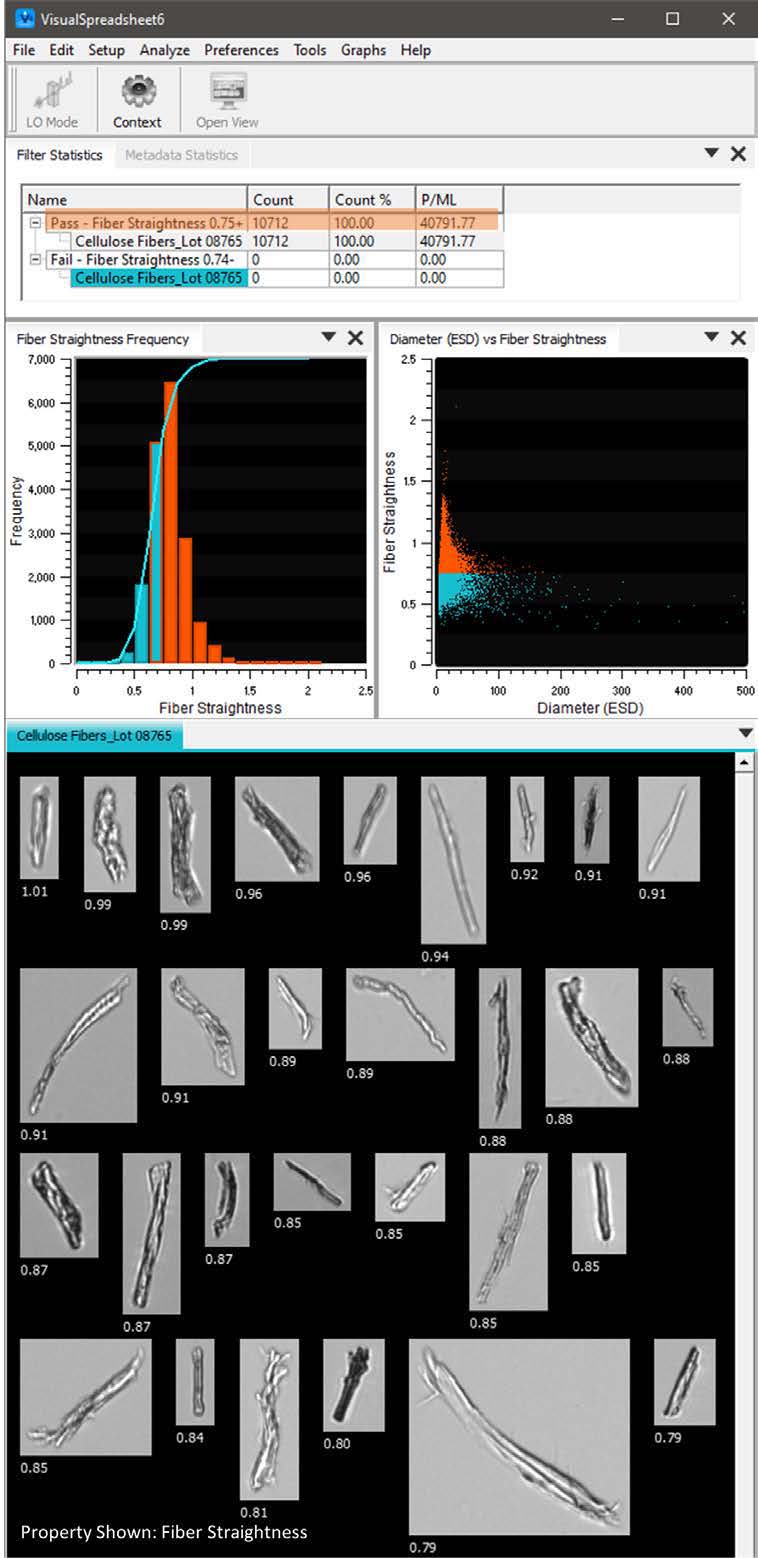

An added benefit of VisualSpreadsheet is the ability to directly

interact with the filter grid and data plots. By selecting the “Pass –

Fibre Straightness 0.75+” filter, particle images that match the filter

will automatically display in the View Window (Figure 6, next page).

These particle images can then be sorted, selected, and/or saved.

Regions of histograms or scatterplots that contain particles matching

the filter will also be highlighted. Data can be easily exported into

Excel or as a PDF document for a seamless reporting and archiving

process.

Conclusion

FlowCam is a powerful analytical tool that expedites and streamlines

fibre analysis. Integrated fibre morphology parameters include

geodesic length, geodesic thickness, fibre straightness, and fiber curl.

Using these measurements, FlowCam provides more accurate and

reliable data than volumetric-based methods and offers a significant

time-savings over manual microscopy. The option of building custom

filters in VisualSpreadsheet allows for instantaneous reporting of

results at the conclusion of sample analysis, saving users time and

effort in assessing fiber quality.