Bettersize

Bettersizer 2600

Laser Diffraction and Dynamic Image Analysis

- Wet dispersion: 0.02 to 2,600µm

- Dry dispersion: 0.1 to 2,600µm

- Dynamic Imaging 2.0 to 3,500µm

The Bettersizer 2600 utilises proven Laser Diffraction Technology to measure particle sizes ranging from 0.02 to 2,600 μm. Its modular design provides versatile functionality, with the dynamic imaging module enabling combined laser and imaging tests. This extends the measurement range to 3,500 μm while allowing for both particle size and shape analysis. Additionally, the system’s flexible dispersion modules support both dry and wet dispersion methods, catering to a wide range of measurement needs.

-

Key Features

TechnologyLaser Diffraction

Particle size rangeWet dispersion: 0.02 to 2,600 µm Dry dispersion: 0.1 to 2,600 µm

Sample stateWet and dry method of particle sizing is suitable for a wide variety of dispersing particle systems

RangePrecise measurement of both large and small particles covering the broadest range by a new patented technology utilizing both Fourier and Reverse Fourier optical systems

DetectorsOptical bench with 92 detectors covering an angular range of 0.016° – 165° Optional wet and/or dry dispersion

Small VolumeSmall volume dry dispersing module for small sample quantities especially for pharmaceutical or valuable samples in short supply

SpeedEasy and fast to changeover between dispersing modules

SOP’sEasy to implement, create and use Standard Operation Procedures for new materials

Refractive Index MeasurementRefractive index measurement for providing a more accurate parameter to calculate the results.

Software -

Specification

Particle size distributionSuspensions, emulsions, dry powders

PrincipleLaser diffraction technology

AnalysisMie scattering theory and Fraunhofer diffraction theory

Measurement timeLess than 10 seconds

Measuring rangeWet dispersion: 0.02 to 2,600 µm Dry dispersion: 0.1 to 2,600 µm

Accuracy error≤ 0.5% *

Repeatability≤ 0.5% *

Number of size classes100 (user adjustable)

Feeding modeAutomatic circulation or micro cuvette (wet)

Gas transportation (dry)Special functionsSOP settings, refractive index measurement, sample ratio calculation)

Optical SystemCombined Fourier and inverse Fourier & Tilted sample cell

LaserHigh-power optical fiber laser (10 mW / 635 nm)

Detector92 detectors (forward, lateral and backward arrangements)

Measuring Angle0.016 – 165°

Measurement methodOne-click operation (automated measurement, cleaning, saving, printing, etc.)

Dispersion mediumWater or organic solvents (sample dependent)

Circulation300 – 2500 r/min

UltrasonicationDry burning prevention,50 W

Dispersion mediumAir/ Nitrogen/Noble gas

Air pressure0.1 – 0.8 MPa (Air compressor dependent)

Conformity21 CFR Part 11, ISO 13320, USP <429>, CE

ReportsCustomisable reporting

Dimensions70.5 x 31.8 x 29.5 cm

Weight23 kg

Supply voltage100 – 240V, 50/60 Hz

Weight52 lbs (23.5 kg)

Computer InterfaceAt least one high-speed USB 2.0 or USB 3.0 port required

Operating systemWindows 7 (32 bit and 64 bit) or higher

Hardware specificationIntel Core i5 Processor, 4GB RAM, 250GB HD, Wide screen monitor

-

Accessories

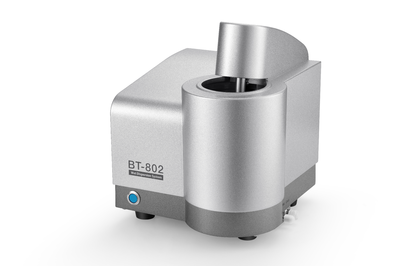

BT-802

Wet method

600mL (dispersion medium)

Fully automated

BT-804

Wet & small volume

8mL (dispersion medium)

Semi-automated

BT-80N

Anti-corrosive

80mL (dispersion medium)

Semi-automated

BT-902

Dry method

0.2 – 10 g (sample)

Fully automated

BT-903

Dry & small volume

0.02 – 1 g (sample)

Fully automated -

Applications

-

Technology

Not sure if it’s the right instrument?

No worries, send us a sample and we will test it for you

Send a sample-

Outstanding service

I have been using Meritics for a number of years and they always provide outstanding service and support.

They have a rapid response turnarounds and are very knowledgeable of the techniques and products they provide.LeanneB-375

-

Good service, very helpful

We use Meritics for the PM service and installation of all our FlowCams . Megan has been coming to our site for a number of years. She is very efficient in her work, but most of all Megan is very helpful. We have had issues with one of instruments after the install and Megan did her utmost to try and solve it while on site, even though it wasn’t solved Megan has been in contact with the supplier of the instrument to try and solve this problem for us.

SophieH-2201

-

Job done in a friendly manner

Booking engineer visits is always easy. David Lowe, Meritics engineer is always very friendly.

ThierryN

-

Service/calibration visit

Excellent service, arrived on time, polite, friendly and informative.

NathamM-270

-

5 Stars

Excellent service from an excellent company. Would recommend them to anyone.

BarryH-480

-

Good Service

David, our service engineer as usual was good at communicating and setting up the recent service appointment, he arrived on time, did the service promptly and informed me of any problems. Friendly and helpful

TomA-446

-

Superb and prompt service

I have used this company through the laboratory I work for frequently. We specialise in soil analysis, and Meritics were chosen as they have extensive knowledge of the instruments we use. We have several laser particle diffraction analysers with a service contract, and service is always very prompt and meticulous….

JamesG-2483

-

Good experience over two years

Meritics have covered the annual servicing of our Multisizer 4e instrument since we purchased it from them just over two years ago. The application scientist who performed the servicing was friendly, knowledgeable, and extremely helpful, happily answering a barrage of questions about how best to use and maintain the instrument. All my interactions with Meritics staff have been positive. I would happily recommend them.

RajG-62

-

Fully committed to customer service

Service second to none, both units serviced and all questions answers by engineer while on site.

RichardA-786

-

Highly recommend Meritics for equipment purchases and aftercare services

After owning one of our instruments for over 8 Years which was purchased from Meritics, it suffered its first breakdown. Upon contacting Meritics, I was instantly put through to an engineer who was very helpful. Upon inspection of the manual, it was decided that it would be more cost effective to have a Meritics engineer visit. The Meritics staff were very communicative and kept me up to date.

-

Excellent Service

Lovely, friendly and extremely helpful. David and his team are always on call with advise and are very easy to work with and are always happy to help.

NaomiT-64

-

Service of lab equipment

Excellent service. Friendly and professional service was provided in a timely manner to the expected standard.

NathanM-270

-

Excellent

Excellent communication. Updates given well in advance. Very polite staff and engineers.

NathanM-270

-

Multisizer 4e install at pharmaceutical company

2 people helped with the install of a Multisizer 4e. They were both very professional and friendly, answering any questions that I had. The installation was quick and the attention to good documentation practice was exceptional.

Chloel-9

-

Service of Beckman Coulter instruments

Always a pleasure to welcome the Meritics service engineer, who is knowledgeable, personable and extremely competent.

NeilT-394

-

Professional

Friendly and collaborative staff, provided a very good service.

SamK-403

-

Professional, Customer-oriented, fast service

We had issues with one of the aperture tubes provided by Meritics on a Friday afternoon, while very pressed for a review deadline. Meritics handled our inquiries very fast and professionally and helped us out by shipping us their spare tube to use in the mean time free of charge, while we waited for our new tube to arrive. Communication was very pleasant.

VeerleB

-

Very helpful and prompt

I emailed for some technical help and also to get some spares and both the engineer (David) and purchasing (Sophie) were very prompt to respond and helpful. We do have a service contract but I appreciated being able to email the engineer directly.

AlexH-474

-

Excellent Service

Used Meritics to conduct particle size distribution by laser diffraction. Service as last time, is very quick, well priced and professional.

I would highly recommend

GavinR-101

-

Excellent and Friendly Service

Always a pleasure to deal with the people at Meritics Ltd. They understand the importance of our work and the fact that our research projects have deadlines that need to be met. Consequently, problems are dealt with very quickly and professionally and they are willing to go that one step further to make sure their supply chain problems don’t become our problems. Thank you to the team for their support. It is greatly appreciated.

JanetH-255