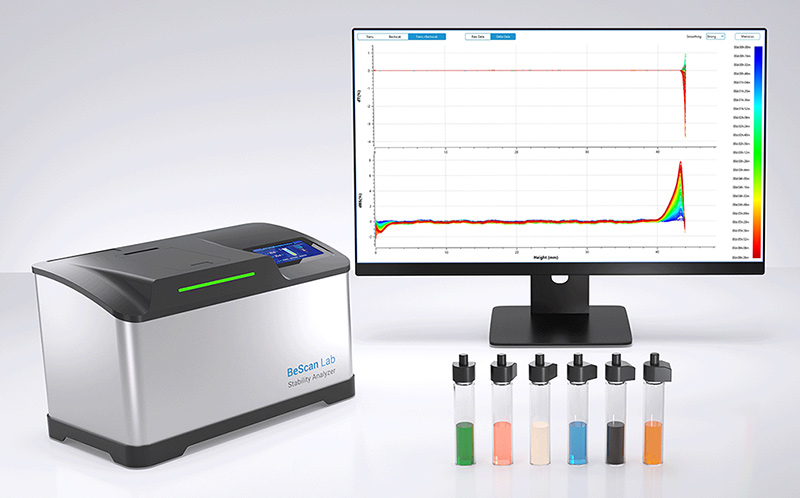

Bettersize BeScan Lab

Stability Analyser

- Particle range 0.01 to 1,000 μm

- Non-destructive stability analysis

- Quantification of destabilisations and study of kinetics

BeScan Lab, the versatile, sensitive, and reliable stability analyser based on Static Multiple Light Scattering (SMLS) technology, is widely used in the formulation development and product quality control. It accommodates a wide range of sample concentrations up to 95% v/v and types such as emulsions, suspensions, and foams, with temperature scanning capabilities reaching up to 80 °C. BeScan Lab provides both qualitative analysis and quantification of destabilisation, helping you monitor long-term product stability and achieve optimal shelf life.

Features and Benefits

● Real stability analysis for dispersions with volume fraction up to 95%

● Particle size measurement range from 0.01 to 1,000 μm

● Non-destructive stability analysis: Non-contact, non-dilution, non-shearing

● 20 µm resolution data acquisition enables quicker sample stability observation than the naked eye

● Temperature control up to 80 °C to accelerate destabilisation

● Identification of various unstable phenomena: creaming, sedimentation, flocculation, coalescence, and phase separation

● Quantification of destabilisations and study of kinetics

-

Key Features

What BeScan Lab Provides?

- lnstability index (lus)

- Mean particle size

- Hydrodynamic analysis

- Radar chart for regional lus

- Temperature trend testing

- Particle migration rate

Why You Need It?

From Raw Materials to Finish

BeScan Lab plays a crucial role throughout the product lifecycle, supporting formulation, production, and pre-use stages. It enables formulation optimization, quality control during manufacturing, investigation into optimal transportation and storage conditions, and research on redispersibility

1. Research and development

Ensure excellent dispersibility and uniformity through raw material selection.

2. Production and quality control

Optimize production processes, including method, time, and temperature, to enhance efficiency.

3. Storage and transportation

Evaluate formulation stability under varying environmental conditions, observing destabilization, and predict shelf life.

4. Pre-use treatment

Study the reversibility of destabilization and compliance with usage standards.

Features & Benefits

Non-destructive stability analysis for various dispersions

- Non-contact, non-dilution, non-shearing

- Sample volume fraction up to 95%

- Particle size measurement range from 0.01 to 1,000 μm

Fast and direct stability measurement

- The high-performance LED and ultra-sensitive detectors, with a 20-micron scan step, allow real-time monitoring and capture of subtle variations 200 times faster than the naked eye

- Temperature control up to 80 °C to accelerate destabilization

Qualitative and quantitative stability results

- Identification of various unstable phenomena, such as creaming, sedimentation, flocculation, coalescence, and phase separation

- Quantification of destabilizations and study of kinetics

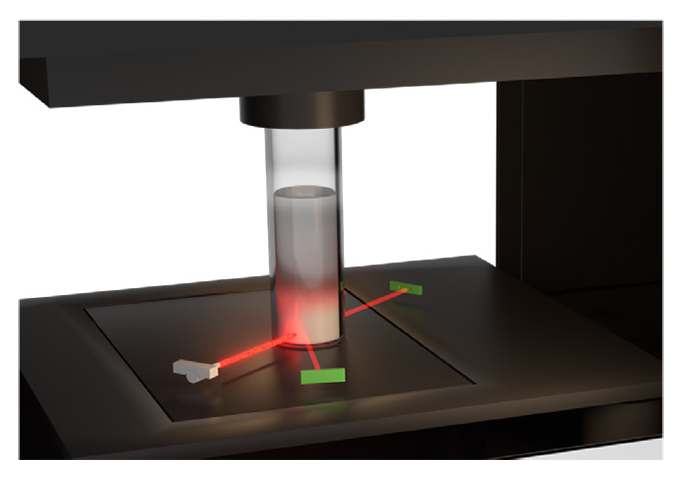

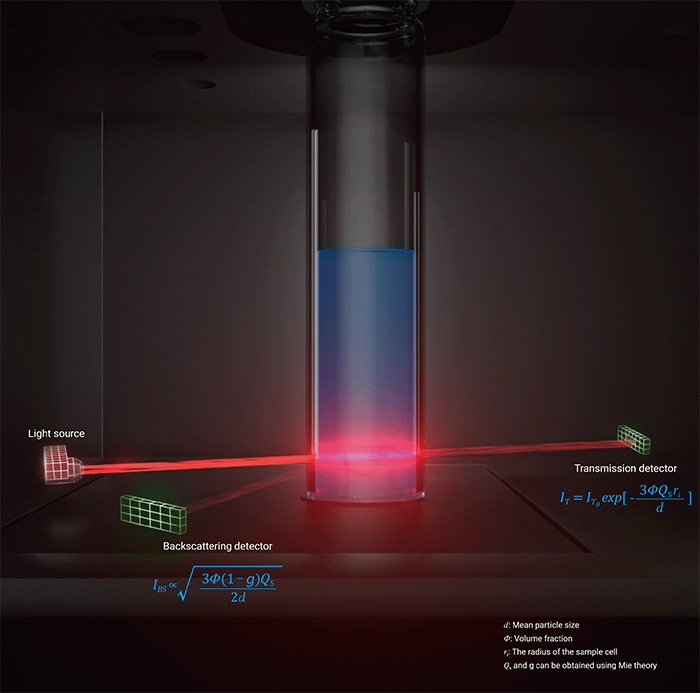

Advanced Measurement PrincipleStatic Multiple Light Scattering (SMLS) is employed to characterize the stability of dispersions. Within BeScan Lab, a setup comprising two detectors and an LED light source ascends along the sample cell to conduct sample scanning. In the case of concentrated samples, the backward detector is employed to detect backscattered signals, while for diluted samples, the forward detector is utilized to detect transmitted signals.

Versatile Applications

- Agrochemicals

Evaluate the stability of pesticide formulations to predict shelf life and ensure the consistent performance of suspension systems.

- Battery and Energy

Test the stability of electrode materials and electrolytes, crucial for enhancing battery performance and lifespan.

- Ceramics

Analyze the stability of ceramic slurries and monitor the stability of glazes and pigments, ensuring reliable production processes.

- Home and Personal Care

Ensure product stability in cosmetics, lotions, creams, and other formulations for reliable performance.

- Food and Beverage

Test the stability of food products, from milk to sauces, and assess the dispersibility of food powders to maintain product quality.

- Petrochemicals

Monitor and ensure the stability of oil products, providing critical insights into the long-term performance of lubricants and the behavior of polymers in oil.

- Pharmaceuticals

Conduct stability testing for medicinal formulations, assess long-term drug stability, and analyze biomacromolecule aggregation to ensure product efficacy.

- Paints, Coatings and Inks

Measure the stability of coatings and inks, and evaluate the dispersion of pigments and dyes for uniform product quality.

-

Technology

Static Multiple Light Scattering

Static Multiple Light Scattering (SMLS) is an optical technique used to directly characterize native concentrated liquid dispersions. This technique emits light into the sample, where it is scattered multiple times by particles or droplets before being detected.

BeScan Lab applies SMLS using an 850 nm LED as light source, with detectors set at 0° for capturing transmitted light and at 135° for backscattered light. This setup scans the sample vertically, analyzing the transmitted light for transparent systems, while the backscattered light is ideal for opaque systems.

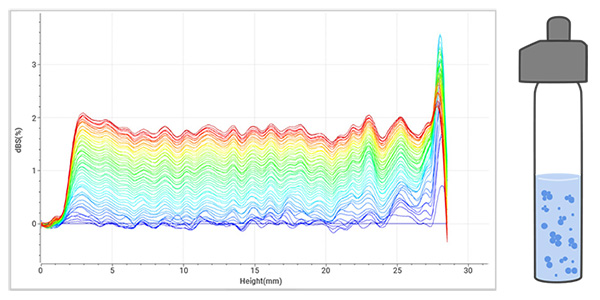

The signals are collected at 20 μm intervals, which enables precise observation of changes in size (d) and concentration (Φ) of suspended materials.

Signal display

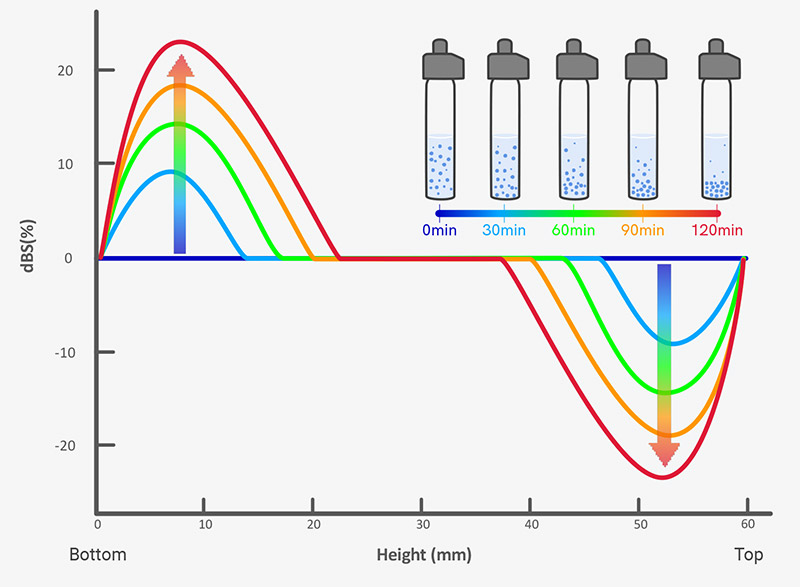

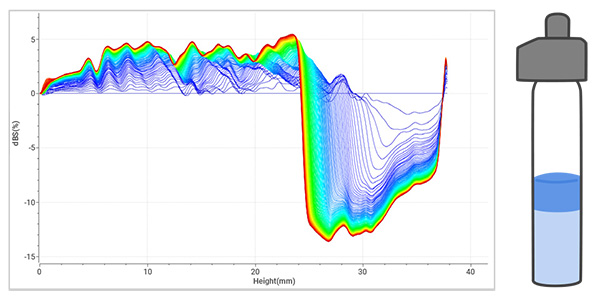

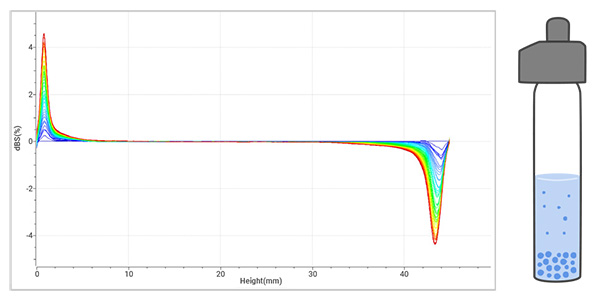

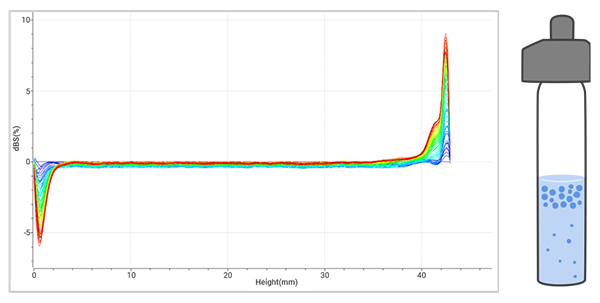

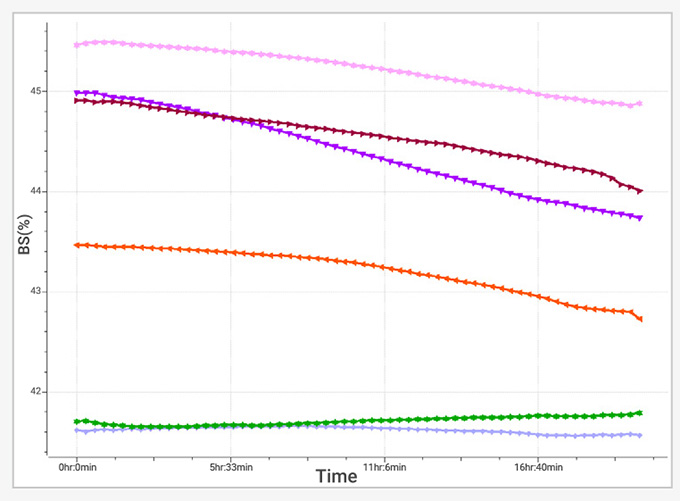

Customized scanning procedures allow presentation of scans with different colors corresponding to different scanning times. The overlap of scans demonstrates how signals diverge from the reference as they vary with height and time. Intuitively, the scans capture local changes that characterize unstable phenomena.

The example illustrates that during sedimentation, the backscattered signals (dBS) undergo a distinctive pattern of change: a decrease at the top and an increase at the bottom, which is attributed to the migration of particles.Features

- Versatile measurement

No limitations on color or viscosity, and suitable for a wide range of samples from low to high concentrations (up to 95% v/v).

- Non-destructive and in situ

Measures without preparation, thus preserving the sample’s original characteristics.

- Wide particle size range

Capable of measuring particles from 0.01 to 1,000 μm.

- Applicable to various systems

Suitable for emulsions, suspensions, foams, and other dispersions, providing robust and high-resolution measurements.

-

Software

Dedicated Software

for Superior Qualitative and Quantitative Stability Outcomes

Qualitative Analysis – Identification of Destabilisation

BeScan Lab utilises near-infrared light and a precise 20-micrometer spatial resolution to detect early-stage destabilisation phenomena like phase separation, sedimentation, creaming and aggregation (flocculation, coalescence, and coagulation) well before they are visually observable.

1. Flocculation often results in uniform changes in transmitted or backscattered signals across the entire sample height.

- Common in wastewater treatment, electrode slurries, and drilling fluids.

2. Phase separation typically involves evolving interfaces between phases over time.

- Common in paints and coatings, cosmetics.

3. Sedimentation causes a decrease in backscattered signals at the top and an increase at the bottom in opaque samples.

- Common in slurries, pigments, pesticides, vaccines, and body lotions.

4. Creaming in opaque samples enhances backscattered signals while lowering bottom signals.

- Common in milk-based beverages, lipid emulsions, and pesticides.

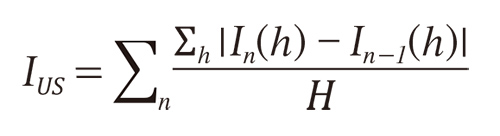

Quantitative Analysis – Instability Index for Rating Guide

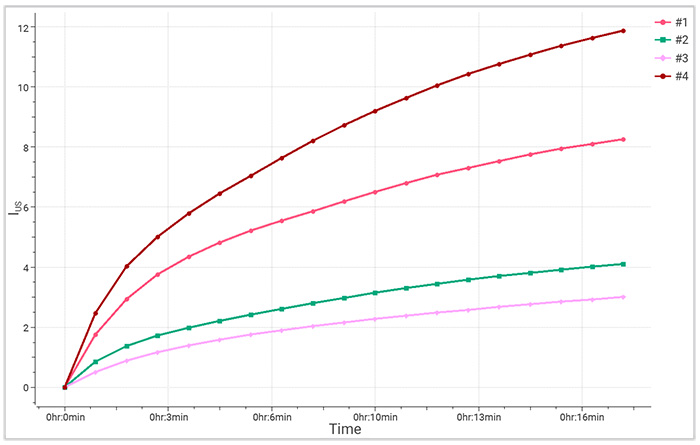

BeScan Lab provides the instability index (IUS), which quantifies the stability of dispersions. The calculation involves summing all signal variations across the entire sample height and over time, capturing all subtle variations within the sample. This facilitates sample comparison, as a greater instability index (IUS) indicates lower stability. An instability index is automatically calculated after every scan using the following formula:

BeScan Lab offers instability indices over time to compare the stability of different samples. A slower increase in the instability index indicates higher dispersion stability, resulting in a flatter curve. Analysing the trend allows for predicting long-term stability.

Time-dependent instability index

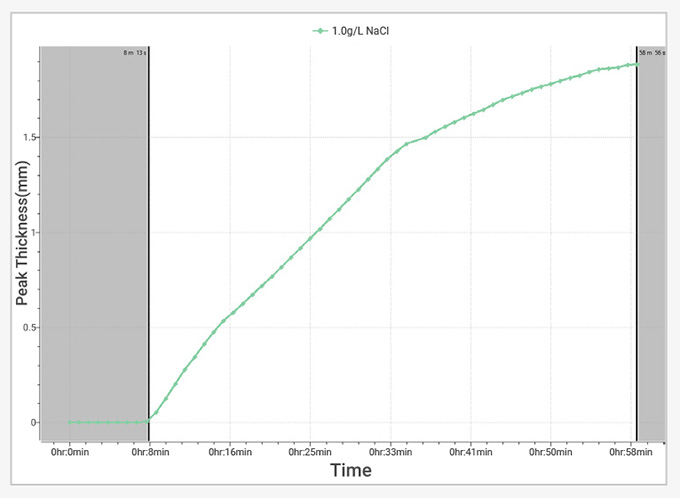

1. Phase separation dynamics and mean particle size

Hydrodynamic analysis reveals layer thickness and particle migration rate over time, thereby determining the hydrodynamic mean diameter.

2. Optical analysis and mean particle size variation

Particle size variation analysis is achievable with BeScan Lab, correlating transmitted and backscattered light signals.

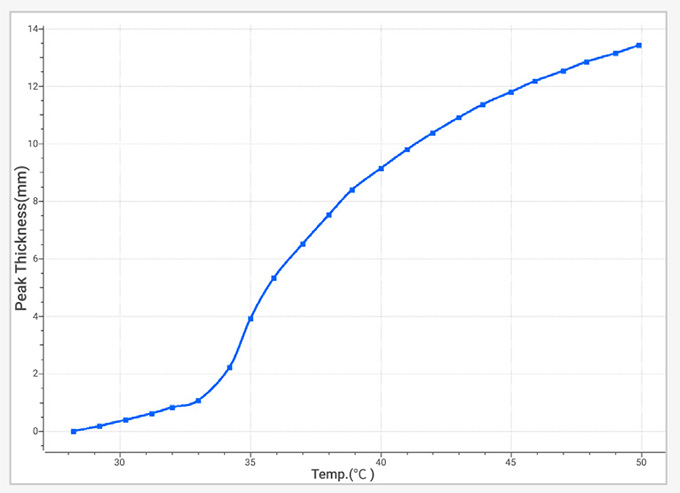

3. Temperature trend measurement

Programmable temperature trend measurement up to 80°C, which explores stability under extreme conditions and accelerates destabilisation.

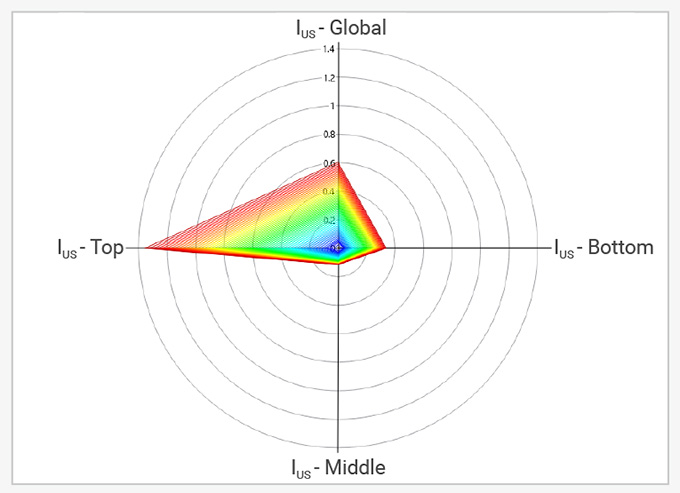

4. Radar chart

Global and regional instability indices for each scanning are illustrated in form of a radar chart, intuitively providing a way to investigate regional stability (top, middle, and bottom).

-

Specification

Parameters Values Measurement principle SMLS (Static Multiple Light Scattering) Detection angle 0° transmission and 135° backscattering Light source 850 nm LED Scan step 20 μm Scan height 0 – 60 mm Number of samples 1 Maximum volume fraction* 95% Measurement range of particle size 0.01 – 1000 μm Temperature range RT – 80 ℃ (±0.5 ℃ ) Sample volume 4 – 25 mL Measurement mode Regular/Fixed point/Temp. trend Dimension 460(L) x 260(W) x 280(H) mm Weight 13.5 kg Power AC100 – 240 V, 50 – 60 Hz, 3.8 A ISO compliance ISO/TR 18811:2018, ISO/TR 13097:2013

ISO/TR 21357:2022, ISO/TS 22107:2021

* Sample and sample preparation dependent

-

Applications

Not sure if it’s the right instrument?

No worries, send us a sample and we will test it for you

Send a sample-

Outstanding service

I have been using Meritics for a number of years and they always provide outstanding service and support.

They have a rapid response turnarounds and are very knowledgeable of the techniques and products they provide.LeanneB-375

-

Good service, very helpful

We use Meritics for the PM service and installation of all our FlowCams . Megan has been coming to our site for a number of years. She is very efficient in her work, but most of all Megan is very helpful. We have had issues with one of instruments after the install and Megan did her utmost to try and solve it while on site, even though it wasn’t solved Megan has been in contact with the supplier of the instrument to try and solve this problem for us.

SophieH-2201

-

Job done in a friendly manner

Booking engineer visits is always easy. David Lowe, Meritics engineer is always very friendly.

ThierryN

-

Service/calibration visit

Excellent service, arrived on time, polite, friendly and informative.

NathamM-270

-

5 Stars

Excellent service from an excellent company. Would recommend them to anyone.

BarryH-480

-

Good Service

David, our service engineer as usual was good at communicating and setting up the recent service appointment, he arrived on time, did the service promptly and informed me of any problems. Friendly and helpful

TomA-446

-

Superb and prompt service

I have used this company through the laboratory I work for frequently. We specialise in soil analysis, and Meritics were chosen as they have extensive knowledge of the instruments we use. We have several laser particle diffraction analysers with a service contract, and service is always very prompt and meticulous….

JamesG-2483

-

Good experience over two years

Meritics have covered the annual servicing of our Multisizer 4e instrument since we purchased it from them just over two years ago. The application scientist who performed the servicing was friendly, knowledgeable, and extremely helpful, happily answering a barrage of questions about how best to use and maintain the instrument. All my interactions with Meritics staff have been positive. I would happily recommend them.

RajG-62

-

Fully committed to customer service

Service second to none, both units serviced and all questions answers by engineer while on site.

RichardA-786

-

Highly recommend Meritics for equipment purchases and aftercare services

After owning one of our instruments for over 8 Years which was purchased from Meritics, it suffered its first breakdown. Upon contacting Meritics, I was instantly put through to an engineer who was very helpful. Upon inspection of the manual, it was decided that it would be more cost effective to have a Meritics engineer visit. The Meritics staff were very communicative and kept me up to date.

-

Excellent Service

Lovely, friendly and extremely helpful. David and his team are always on call with advise and are very easy to work with and are always happy to help.

NaomiT-64

-

Service of lab equipment

Excellent service. Friendly and professional service was provided in a timely manner to the expected standard.

NathanM-270

-

Excellent

Excellent communication. Updates given well in advance. Very polite staff and engineers.

NathanM-270

-

Multisizer 4e install at pharmaceutical company

2 people helped with the install of a Multisizer 4e. They were both very professional and friendly, answering any questions that I had. The installation was quick and the attention to good documentation practice was exceptional.

Chloel-9

-

Service of Beckman Coulter instruments

Always a pleasure to welcome the Meritics service engineer, who is knowledgeable, personable and extremely competent.

NeilT-394

-

Professional

Friendly and collaborative staff, provided a very good service.

SamK-403

-

Professional, Customer-oriented, fast service

We had issues with one of the aperture tubes provided by Meritics on a Friday afternoon, while very pressed for a review deadline. Meritics handled our inquiries very fast and professionally and helped us out by shipping us their spare tube to use in the mean time free of charge, while we waited for our new tube to arrive. Communication was very pleasant.

VeerleB

-

Very helpful and prompt

I emailed for some technical help and also to get some spares and both the engineer (David) and purchasing (Sophie) were very prompt to respond and helpful. We do have a service contract but I appreciated being able to email the engineer directly.

AlexH-474

-

Excellent Service

Used Meritics to conduct particle size distribution by laser diffraction. Service as last time, is very quick, well priced and professional.

I would highly recommend

GavinR-101

-

Excellent and Friendly Service

Always a pleasure to deal with the people at Meritics Ltd. They understand the importance of our work and the fact that our research projects have deadlines that need to be met. Consequently, problems are dealt with very quickly and professionally and they are willing to go that one step further to make sure their supply chain problems don’t become our problems. Thank you to the team for their support. It is greatly appreciated.

JanetH-255