Industry Information

Advanced Materials

Why particle characterisation is important in advanced materials industries

Particle characterisation is fundamental in the field of advanced materials, where precise control and understanding of properties contribute to the development of innovative materials. Meritics has a number of particle characterisation solutions for the industry.

Flow Imaging Microscopy

Flow imaging microscopy enables real-time visualisation and analysis of particle morphology, size distribution, and aggregation dynamics, facilitating precise control over material synthesis, formulation, and performance optimisation.

Laser Diffraction Particle Size Analysis

Particle size analysis in advanced materials ensures precise control over particle dimensions, aiding in tailoring material properties for specific applications such as nanotechnology, pharmaceuticals, and composite materials, enhancing performance and functionality.

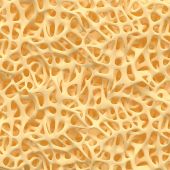

Pore Size Analysis

Pore size analysis in advanced materials enables characterisation of pore structure and distribution, crucial for optimizing material properties like permeability, adsorption capacity, and mechanical strength in diverse applications.

Powder Flow Analysis

Powder flow analysis assesses flow properties crucial for manufacturing processes like compaction, granulation, and coating, ensuring consistency and efficiency in producing high-performance materials.

Surface Area Analysis

Meritics have a range of surface area analysers. Used in advanced materials to quantify available surface area, vital for optimising adsorption, catalysis, and reactivity in applications such as catalysts, batteries, and gas storage materials, enhancing performance and efficiency.

Case study

We use the BeDensi T Pro Series. This improved battery capacity, cycle life, and overall efficiency. As a result, the batteries exhibited enhanced energy density and prolonged lifespan, meeting stringent performance requirements, therefore advancing sustainability and technological innovation.