Sample Analysis

Particle Size

Particle Size Analysis

In all product development, the particle size of products and materials is a critical parameter in their manufacture. Changing the particle size distribution of a material has a massive impact on its characteristics and behaviour either during manufacture, within the final product or on its effects within the environment.

The Meritics Lab offer a range of measurement techniques and particle size analysis testing methods that cover virtually all materials — wet or dry, ranging from >1 nm to 5 mm in size. Our expert scientists can help select the most appropriate test for your material/system from the following:

- Laser Diffraction

- Dynamic Light Scattering

- Electrical Sensing Zone

- Dynamic Imaging

- Sieve

Depending on the technique used, we can report:

- Particle size distribution – weighted to volume, number or surface area

- Polydispersity

Additionally, Meritics offer a fully validated method development service.

Get in touch for a quote or to find out more about how we can support you ….

Laser Diffraction

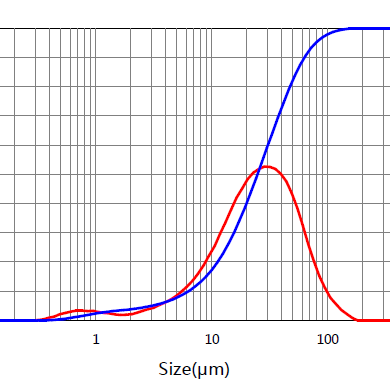

Laser diffraction analysis is based on the Fraunhofer diffraction theory. The intensity of light scattered by a particle is directly proportional to the particle size. The angle of the laser beam and particle size have an inversely proportional relationship, where the laser beam angle increases as particle size decreases and vice versa. The particles are placed in a flow cell between the laser and its focal point. The material is analysed using its laser scatter pattern.

The technique of laser diffraction requires the ability to measure the angle of diffraction of the laser light in order to ascribe a size to the particle. For relatively large particles such as 20µm, this is relatively easy as the intensity minima are well defined, see below:

However, once the size gets below 1µm, there is little or any discernible shape to the intensity ‘curve’ making the discernment of any angular variation virtually impossible below approx. 0.4µm.

Some manufacturers take the intensity data down to this size level and then make effectively; an educated guess; at the data below in order to show something down to 0.1µm. Beckman Coulter developed a patented detection system ‘Polarisation Intensity Differential Scattering’ (PIDS) to overcome the limitations of laser diffraction in this region. Particles scatter polarised light by differing amounts. By combining vertically and horizontally polarised light with multi-wavelength measurements, a much more accurate and reliable measurement can be made below 0.4µm.

The approach has been validated by many of the other manufacturers trying to partially copy this by adding additional wavelength measurements. The most Modern Beckman Coulter LS 13320 XR system can now produce real data down to 10nm using the Patented PIDS system.

Our scientists work with clients across many industries and are experienced in measuring a variety of samples from dry powders such as sugars, soils and sediments to emulsions. If your samples are soluble in water we can measure them in a non-aqueous dispersant, or use a surfactant if it wets poorly. Additionally, we can report means weighted results according to volume, number or surface area.

For submicron particles, the principle of Brownian Motion can be used, as in the Beckman Coulter DelsaMax. Particles suspended in a liquid are in a constant state of random movement or vibration due to the molecular bombardment.

The smaller the particle, the faster it will move. Analysis of the frequency change of scattered laser light pattern is made by auto-correlation spectroscopy, from which average particle size and particle distribution are calculated, the only contestants with this method are the liquids refractive index and viscosity or temperature need to be known. DLS has an overall effective size range of 0.4nmm to 10m.

Our most recent work has been with a lot of university establishments working with crude oil.

Contact us for a quote or to discuss your particle sizing needs.

Electrical Sensing Zone

Beckman Coulter Multisizer 4e, with a range of 0.2µm to 1600µm is widely used in many areas: Life Sciences such stem cells, cell biology, and Industrial such as toner, ceramics, sediments etc. as well as Pharmaceutical applications.

The Coulter Principle (also known as ESZ – Electrical Sensing Zone) is hailed as probably the most significant advance in the field of particle technology, and tens of thousands of Coulter Counter instruments are in regular use worldwide.

Most recently our scientists have been running a lot of water samples on the Multisizer 4e to measure contaminants.

Contact us for a quote or to discuss your particle sizing needs.

Spectradyne’s nCS2TM has taken the Coulter Counter method and re-engineered the principle, it is now possible to count and size individual particles down to 50nm.

The Spectradyne nCS2TM instrument provides a unique platform for the rapid quantitative measurement of Nanoparticle size in solution.

The instrument measures individual nanoparticles to produce particle size distributions with quantitative concentration information for particles from 40nm to 2000nm in size. Not relying on optical technology, the Spectradyne system can be used for protein aggregation studies, extracellular vesicle analysis, nanomedicine, virus studies etc.

Disposable microfluidic cartridges eliminate cross contamination and make operation simple and straightforward from just 2-3µl of sample.

Spectradyne’s nCS2 instrument and associated analysis cartridges, are based on Spectradyne’s patented nanoparticle analyser (NPA) technology. The heart of the instrument is the microfluidic cartridge, which allows the electrical detection of nanoparticles as they pass one by one through a nanoconstriction. Particles larger than the nanoconstriction are removed before reaching it by filters that are built into the cartridge.

No pre-filtering of the sample is required by the user.

Contact us for a quote or to discuss your particle sizing needs.

Dynamic Imaging

Today microscopic examination and counting and sizing of small particles is commonplace, Meritics work with Yokogawa Fluid Imaging Technologies (YFIT) and their FlowCam Image Analyser range can size from 300nm to 5mm in range, this takes the tedium involved away and frees up the scientist to analyse data comprehensively.

Electron microscopes probe the size range below the limit of optical microscopy and a scanning technique enables pictures of the surface features of even very delicate surfaces to be made in exquisite detail.

Most recently our scientists have been sizing sugar samples on the FlowCam 8000 to measure the size and to give an image of the particles.

Contact us for a quote or to discuss your particle sizing needs.

Sieves

For the characterisation of bulk goods of different forms and sizes, the knowledge of their particle size distributions is essential. The particle size distribution, i.e. the number of particles of different sizes, is responsible for important physical and chemical properties such as solubility, flowability and surface reaction.

In many industries such as food, pharmaceuticals and chemistry traditional sieve analysis is the standard for production and quality control of powders and granules. Advantages of the sieve analysis include easy handling, low investment costs, precise and reproducible results in a comparably short time and the possibility to separate the particle size fractions. Therefore, this method is an accepted alternative to analysis methods using laser light or image processing.

Contact us for a quote or to discuss your particle sizing needs.