Horiba Scientific

SA-9600

BET Flowing Gas Surface Area Analysers

- Fully automatic

- Lowest cost ownership

- No user calibration requires

The surface area of a material is, in many cases, as important as the chemical properties. As particle size decreases, surface area increases. Porosity of materials – from micropores to macropores – contribute even more to the total surface area. The interface at the surface is what defines how a solid reacts to other substances, be they gases, liquids, or solids.

Surface area can impact shelf life, stability, dissolution and efficacy of pharmaceutical powders and tablets. Likewise, surface area can affect the rheological properties and hiding powers of pigments, paints, and coatings. It has a significant impact on the ability for materials like catalysts, adsorbents, filtration materials and air separation products to react in the designed application. Ceramics used in applications ranging from; dinner plates, to dental implants, to electronics, all are affected by surface area.

While particle size is frequently used to control size reduction and milling of minerals and other substances, surface area can provide substantial size reduction feedback. Many times, a material which may have the same particle size across different batches may reveal completely different surface areas due to small changes in processing.

The HORIBA Solution

The SA-9600 series of surface area analysers brings exceptional speed, convenience, and low cost-per-analysis to surface area measurement on a wide variety of materials. Now you can perform ultra-fast single or multi-point surface area measurements with push-button ease.

These tools use the robust and proven flowing gas method to acquire gas adsorption and desorption data. This information is then used to calculate total surface area utilising the well-known BET method. The advantage of the flowing gas method is most evident in single-point mode where up to thirty sample analyses can be performed per hour.

The patented SA-9600 technology provides routine total surface area determination in as little as two to six minutes. The SA-9603 models feature three stations for three simultaneous surface area measurements.

-

Features

Fully Automatic

Begin analyses with simplicity. The SA-9600 does the rest! The entire analysis is completed without further interaction and avoids the manual steps required with many similar analysers.

Small Footprint

Laboratory bench space is at a premium in most labs. The SA-9600 provides all analysis and preparation stations in one small, well-designed cabinet. No need for additional space for separate analysis and preparation devices as with many alternative analyzers. If expansion is needed, additional stations are added in the same footprint – not by adding more devices which consume more space on the lab bench. The SA-9600 may also be controlled from the built-in computer and keyboard saving additional space in your lab.

No User Calibration Required

To ensure repeatable accuracy, the SA-9600 performs an automatic calibration before every measurement. And from there, the SA-9600 technology eliminates variables otherwise introduced by operator involvement.

Lowest Cost of Ownership

The use of mass flow controllers in some versions of the SA-9600 series automatically create the necessary mixtures of nitrogen and helium for multi-point BET surface area analysis. This lowers the total cost of ownership by eliminating the need to purchase expensive gas mixtures. Straight forward design ensures service costs are minimal compared to more complex, static volumetric technology.

Detector Protection

An automated bypass loop and cell detector switch limits the effects of missing or broken sample cells by bypassing the detector when gas flow to the cell stops.

Electronic Valves

Reliable electronic valves eliminate the need for a compressed air or gas supply to actuate valves during the measurement process, further lowering cost of ownership.

Improved Gas Handling

Thoughtful design of manifold layout and valve selection result in more stable, balanced flow, improving repeatability, lowering maintenance costs, and easing operation.

Robust Dewar Elevator System

A rugged mechanical design means smoother and reliable movement of the Dewar tray that raises and lowers the LN2 Dewars.

Software Control

The SA-9600 software was designed to be easy as 1, 2, 3.

- Type sample name

- Choose measurement type

- Click “Start”

And in a few minutes the full surface area report will be complete.

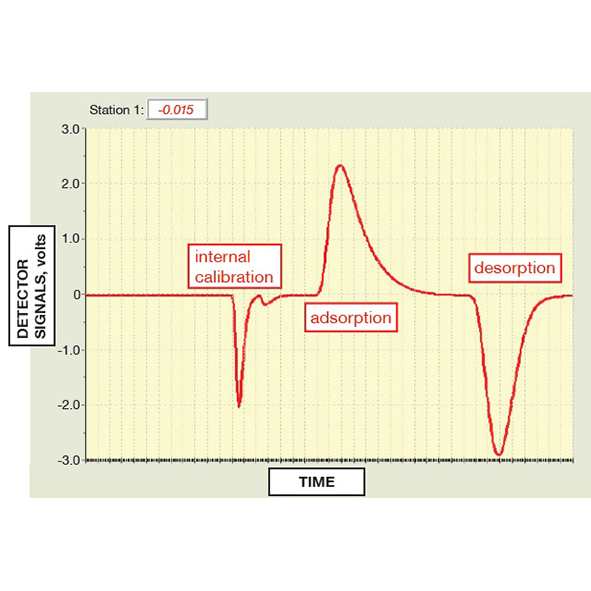

View the measurement in real-time to see the auto-calibration, adsorption, and desorption.

Flexibility

Built-in functions allow optimization of system for different sample types.

- Gas concentration of mixed gases may be precisely controlled to give results identical to the multipoint method.

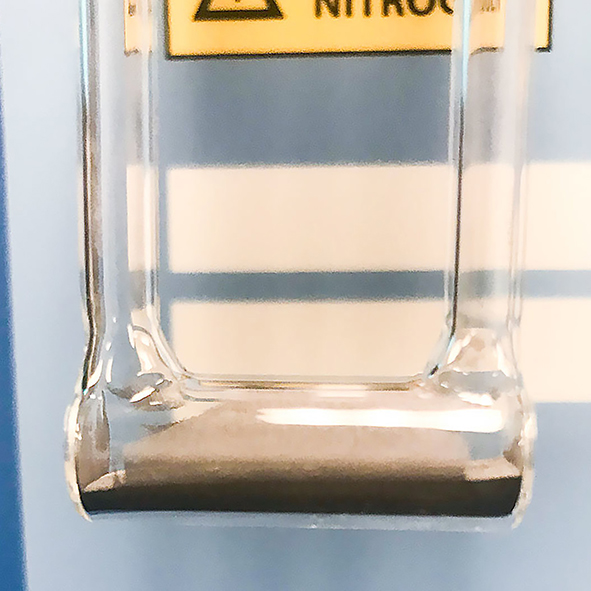

- A wide variety of sample cells are available, allowing measurements to be made on diverse sample types.

Use the feature-rich SA-9600 software to control the unit via USB communication or use the built-in keyboard and display.

High Throughput

Every SA-9600 model includes multiple sample preparation stations (2 or 3 depending on model). For very high throughput environments the SA-9660 accessory provides three additional stations.

-

Specifications

BET Surface Area Measurement Range

Total Surface Area: 0.1 to 50 m2

Specific Surface Area: Approximately 0.01 – 2,000 m2/g

Much more sensitive to low surface area samples than volumetric type analyzers, allowing the use of samples less than 1g and as low as 0.1 square meters in the sample cell.Accuracy and Precision

Reproducibility is better than 1% COV.

Accuracy is better than 10% for most samples.The SA-9600 Series offers a full line of high-quality, high-performance BET Surface Area Analyzers with four fully automatic analyzers to meet the needs of any research or quality assurance laboratory. The SA-9600 Series analyzers include:

- SA-9601: One sample analysis station, two sample preparation stations.

- SA-9601MP: One sample analysis station, two sample preparation stations, MFC gas mixture control and multi-point analysis.

- SA-9603: Three sample analysis stations, three sample preparation stations.

- SA-9603MP: Three sample analysis stations, three sample preparation stations, MFC gas mixture control and multi-point analysis.

- SA-9660: Three sample preparation stations.

-

Applications

Not sure if it’s the right instrument?

No worries, send us a sample and we will test it for you

Send a sample-

Outstanding service

I have been using Meritics for a number of years and they always provide outstanding service and support.

They have a rapid response turnarounds and are very knowledgeable of the techniques and products they provide.LeanneB-375

-

Good service, very helpful

We use Meritics for the PM service and installation of all our FlowCams . Megan has been coming to our site for a number of years. She is very efficient in her work, but most of all Megan is very helpful. We have had issues with one of instruments after the install and Megan did her utmost to try and solve it while on site, even though it wasn’t solved Megan has been in contact with the supplier of the instrument to try and solve this problem for us.

SophieH-2201

-

Job done in a friendly manner

Booking engineer visits is always easy. David Lowe, Meritics engineer is always very friendly.

ThierryN

-

Service/calibration visit

Excellent service, arrived on time, polite, friendly and informative.

NathamM-270

-

5 Stars

Excellent service from an excellent company. Would recommend them to anyone.

BarryH-480

-

Good Service

David, our service engineer as usual was good at communicating and setting up the recent service appointment, he arrived on time, did the service promptly and informed me of any problems. Friendly and helpful

TomA-446

-

Superb and prompt service

I have used this company through the laboratory I work for frequently. We specialise in soil analysis, and Meritics were chosen as they have extensive knowledge of the instruments we use. We have several laser particle diffraction analysers with a service contract, and service is always very prompt and meticulous….

JamesG-2483

-

Good experience over two years

Meritics have covered the annual servicing of our Multisizer 4e instrument since we purchased it from them just over two years ago. The application scientist who performed the servicing was friendly, knowledgeable, and extremely helpful, happily answering a barrage of questions about how best to use and maintain the instrument. All my interactions with Meritics staff have been positive. I would happily recommend them.

RajG-62

-

Fully committed to customer service

Service second to none, both units serviced and all questions answers by engineer while on site.

RichardA-786

-

Highly recommend Meritics for equipment purchases and aftercare services

After owning one of our instruments for over 8 Years which was purchased from Meritics, it suffered its first breakdown. Upon contacting Meritics, I was instantly put through to an engineer who was very helpful. Upon inspection of the manual, it was decided that it would be more cost effective to have a Meritics engineer visit. The Meritics staff were very communicative and kept me up to date.

-

Excellent Service

Lovely, friendly and extremely helpful. David and his team are always on call with advise and are very easy to work with and are always happy to help.

NaomiT-64

-

Service of lab equipment

Excellent service. Friendly and professional service was provided in a timely manner to the expected standard.

NathanM-270

-

Excellent

Excellent communication. Updates given well in advance. Very polite staff and engineers.

NathanM-270

-

Multisizer 4e install at pharmaceutical company

2 people helped with the install of a Multisizer 4e. They were both very professional and friendly, answering any questions that I had. The installation was quick and the attention to good documentation practice was exceptional.

Chloel-9

-

Service of Beckman Coulter instruments

Always a pleasure to welcome the Meritics service engineer, who is knowledgeable, personable and extremely competent.

NeilT-394

-

Professional

Friendly and collaborative staff, provided a very good service.

SamK-403

-

Professional, Customer-oriented, fast service

We had issues with one of the aperture tubes provided by Meritics on a Friday afternoon, while very pressed for a review deadline. Meritics handled our inquiries very fast and professionally and helped us out by shipping us their spare tube to use in the mean time free of charge, while we waited for our new tube to arrive. Communication was very pleasant.

VeerleB

-

Very helpful and prompt

I emailed for some technical help and also to get some spares and both the engineer (David) and purchasing (Sophie) were very prompt to respond and helpful. We do have a service contract but I appreciated being able to email the engineer directly.

AlexH-474

-

Excellent Service

Used Meritics to conduct particle size distribution by laser diffraction. Service as last time, is very quick, well priced and professional.

I would highly recommend

GavinR-101

-

Excellent and Friendly Service

Always a pleasure to deal with the people at Meritics Ltd. They understand the importance of our work and the fact that our research projects have deadlines that need to be met. Consequently, problems are dealt with very quickly and professionally and they are willing to go that one step further to make sure their supply chain problems don’t become our problems. Thank you to the team for their support. It is greatly appreciated.

JanetH-255