4 Applications of Enhanced Laser Diffraction Analysis

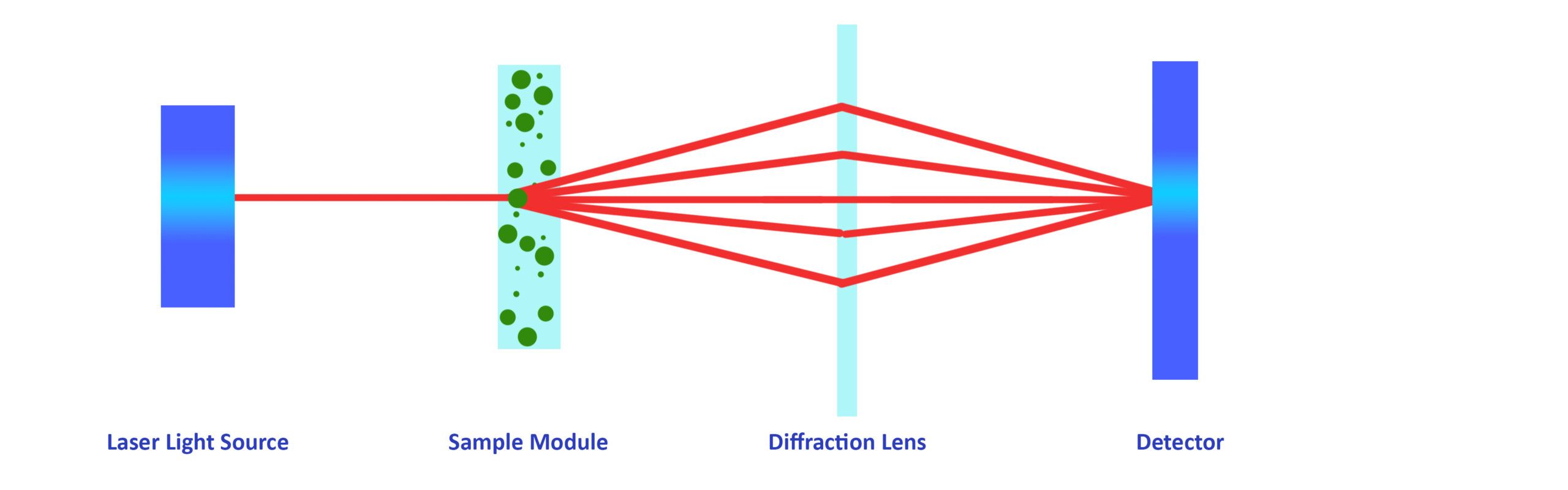

Particles diffract light through a specific angle depending upon their size, creating a diffraction pattern of light and dark circles. Measuring the intensity of light over a wide range of angles enables analysts to determine a particle size distribution. Laser diffraction analysis operates on this general principle.

Mie and Fraunhofer Diffraction Theories

Gustav Mie’s theory of diffraction is used in an array of light scattering applications, including laser diffraction analysis. It requires some knowledge of the particle and suspending fluid’s optical properties to acquire accurate data. An approximation of the Mie theory by Fraunhofer was developed for applications where the size of a particle is larger than the wavelength of light being diffracted. This eliminated the need for prior knowledge of the optical properties as they have minimal effects on data.

Fraunhofer’s approximation of Mie theory is typically used to measure particles of up to 30µm. To provide reliable and accurate particle size distribution measurements, good resolution of the angular pattern of the diffracted light is required, alongside a large number of detectors (>100).

As particle size decreases, the angle through which light is diffracted gets bigger and the intensity smaller, which makes detection of the actual angle of diffraction difficult. Below 1µm, it becomes virtually impossible to distinguish light from different particle sizes, and impossible below 0.4µm. Using more than one wavelength of light helps to quantify this but only marginally and some instruments use curve fitting type routines to estimate data below the measuring limits.

Overcoming the difficulties of measuring sub micron particles

Sub-micron particles scatter polarised light differentially depending on the polarisation and wavelength. Enhanced laser diffraction analysis uses this property to provide real measured size distributions rather than estimates down to 10nm (0.01µm). It measures the intensity of polarised light at 3 additional wavelengths. The difference in intensity between the vertically polarised and horizontally polarised light (Polarisation Intensity Differential Scattering – PIDS) provides information on the quantity and sizes of particles in this region. This can be integrated into the Mie theory calculation for quantifiable size distribution measurements.

This enhanced measurement range provides the basis for dynamic materials characterisation and particle measuring for a broad range of industrial, academic, and commercial sectors.

This blog post will explore four common applications of enhanced laser diffraction analysis.

-

- 1. Soil Studies

The enhanced laser diffraction particle size analyser is used to measure particle or grain size of soil and sediment samples, a property that can be indicative of how a soil has formed.

- 1. Soil Studies

-

- 2. Pigment Sizing

Laser diffraction analysis enabled with polarisation intensity differential scattering (PIDS) can measure particles down to the nanometer scale (nm) by sequentially illuminating a sample with wavelengths of alternately polarised light. This method has been used to reliably size pigment particles as small as 10 nm.

- 2. Pigment Sizing

-

- 3. Quality Control of Chemical Compounds

Enhanced laser diffraction analysis is uniquely suited to quality control (QC) applications with a superior resolution and unmatched dynamic range compared to conventional laser diffraction techniques. It provides a rapid assessment of the particle size distributions in powder or liquid samples, with well over 100 light detectors enabling the resolution of subtle differences in particle size.

- 3. Quality Control of Chemical Compounds

-

- 4. Research and Development

Laser diffraction analysis for R&D purposes can be complex as some instruments require prior knowledge of a sample’s particle size characteristics, such as whether a single peak of particles is expected or if they may be more than one population of particles such as aggregates. The LS 13320 XR enhanced laser diffraction analyser does not require this information. The software carries out complex and comprehensive analysis of the diffraction patterns to provide an accurate particle size distribution without any need for the operator having to guess at the expected result.

- 4. Research and Development

Enhanced Laser Diffraction Analysis with Meritics

Meritics is the UK’s leading supplier of particle analysis instrumentation for an extensive range of applications. We work with cutting-edge technology manufacturers to provide the most advanced measurement systems available.

The LS 13 320 XR is our most enhanced laser diffraction analysis tool. It is capable of performing in all the aforementioned applications and more. If you would like any more information, please do not hesitate to contact us.